For producers of demanding technical yarns, magnification of the yarn evenness with a PolyJet-TG-3-HP405A/WO70 (TopAir) looks stunning. The new generation of jets impresses with an unmatched even and uniform interlacing density as well as with strong, reliable knots for high tenacity yarn (HT and HMLS). Heberlein’s latest PolyJet-TG-3 achieves more than 12 knots per meter with 1100f98dtex and 1670f98dtex. Yarn parameters of tensile strength, elongation, and elasticity show smaller variations, for ultimate quality benefits, as well as improved unwinding behaviour of the bobbins, the company said in a press release.

Typical Heberlein benefits come with all these components. High-performance air interlacing jets for technical yarns offer a unique quick-release system, so jet packs can be exchanged within seconds, with just a single 180° turn. They also feature a compact, space-saving design and a roll bar to protect the ceramic surfaces.

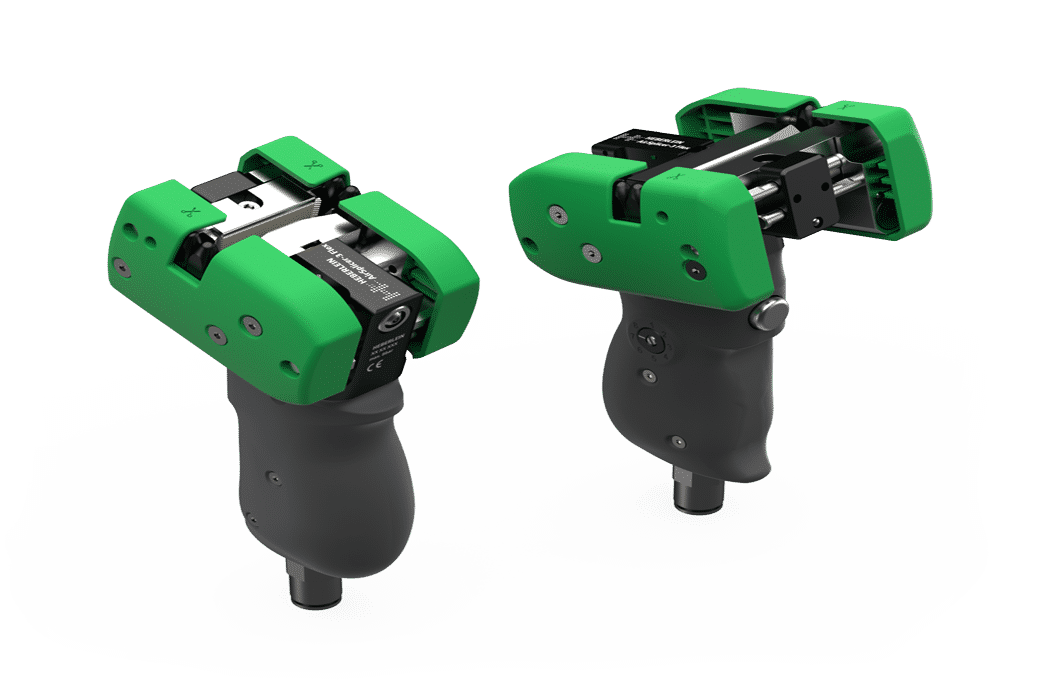

Yarn splicers produce a tear-resistant, homogeneous splice of material without knots. All they need is compressed air. Heberlein’s AirSplicers produce first-class splices for a wide range of applications for technical fibres where extreme strength characteristics are needed.

Synthetic multifilament yarns, aramid, carbon, or glass can all be spliced with AirSplicer-3 Flex. The range covers from 500dtex up to 30,000dtex depending on the material. Flexibility results from its innovative width-adjustable design, ideal for technical and textile multifilament yarns. In one single device, the new splicer replaces two former units, namely AirSplicer 40-2 and 70-2.

Fibre2Fashion News Desk (RR)