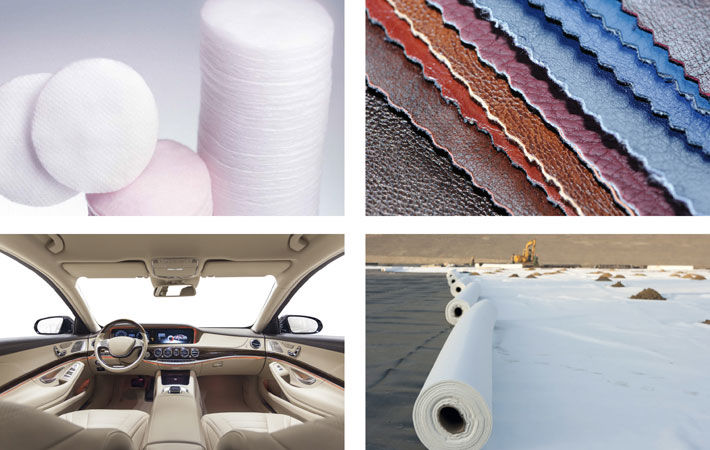

Leading Swiss Textile Machinery firms Autefa, Rieter’s subsidiary Graf, and Uster Technologies have launched innovative technologies in the booming nonwovens sector. according to Swissmem, the to is the leading association for SMEs and large companies in Switzerland’s mechanical and electrical engineering (MEM) industries and related technology-oriented sectors.

Autefa Solutions has launched a fully automatic machine for producing face masks. With V-Jet Futura, the company recently sealed the link in its product range between web forming and drying technology. This latest hydroentanglement machine, together with the SQ-V Square Drum Dryer, embodies advanced technology combined with significant reductions in energy consumption compared to other process solutions, according to a press release by Swissmem.Leading Swiss Textile Machinery firms Autefa, Rieter's subsidiary Graf, and Uster Technologies have launched innovative technologies in the booming nonwovens sector. Swissmem is the leading association for SMEs and large companies in Switzerland's mechanical and electrical engineering (MEM) industries and related technology-oriented sectors.#

A vital contribution to nonwovens production is offered by Graf, a leading supplier of clothing and combs for carding and combing processes in spinning and nonwovens. Graf’s Hipro card clothings, suitable for any man-made fibres in the nonwovens sector, are the answer to demands for higher productivity. Their superior performance delivers up to 10 per cent higher throughput and greater carding efficiency compared to conventional clothings. These reliable card clothing elements also ensure a consistently reproducible high web quality, as well as 20 per cent fewer failures in the web, thanks to the precise fibre transfer to and from the cylinder.

Another constant trend in nonwovens today is the drive for better quality. Manufacturers want to take charge of contamination levels in their processes, as well as eradicating defects which may arise during production. Uster, the leading provider of quality management solutions from fibre to fabric, offers a combined solution to achieve both these required quality standards. At the fibre preparation stage, Uster Jossi Vision Shield N ensures the best possible initial inspection and removal of contamination. Then, at the end of the production sequence, Uster EVS Fabriq Vision N handles automated detection and marking of all the main defects caused during production. This combined solution avoids material waste and takes full advantage of the potential for process optimisation.

“Sustainability and circular economy become key issues in today’s production of nonwovens. We observe an increase in projects with natural fibres such as flax, hemp or jute. In blends, hybrid products with special properties are created. Therefore, successful machine manufacturers also need individual solutions, as well as turnkey lines, for nonwovens manufacturing,” André Imhof, CEO of Autefa Solutions Switzerland and Autefa Solutions Austria said in a statement.

Fibre2Fashion News Desk (GK)