Research centres Trans-Pacific Aerospace Co (TPAC) and ThermoPlastic composites Research Center (TPRC) have developed a new recycling process that targets the production scrap of thermoplastic composites. The objective is to retain the high mechanical properties of the composites and reduce the overall environmental impact at affordable cost.

Research centres Trans-Pacific Aerospace Co (TPAC) and ThermoPlastic composites Research Center (TPRC) have developed a new recycling process that targets the production scrap of thermoplastic composites. The objective is to retain the high mechanical properties of the composites and reduce the overall environmental impact at affordable cost.#

The project will be done in collaboration with industrial partners in the value chain, from material, manufacturing, design and application: GKN Aerospace Fokker Business, TenCate Advanced Composites (Toray Group), Cato Composite Innovations, Dutch Thermoplastic Components and Nido RecyclingTechniek. The project is facilitated by Saxion and with the financial support of Regieorgaan SIA, part of The Netherlands Organization for Scientific Research (NWO), mentions the website of TPAC and TRPC.

Research centres Trans-Pacific Aerospace Co (TPAC) and ThermoPlastic composites Research Center (TPRC) have developed a new recycling process that targets the production scrap of thermoplastic composites. The objective is to retain the high mechanical properties of the composites and reduce the overall environmental impact at affordable cost.#

With the growth of applications and production of thermoplastic composites, the amount of generated scrap increases and reaches substantial volumes. Considering the high commercial value of the scrap as well as legal and environmental reasons, the development of specific recycling solutions is of interest to TPAC and TPRC.

Research centres Trans-Pacific Aerospace Co (TPAC) and ThermoPlastic composites Research Center (TPRC) have developed a new recycling process that targets the production scrap of thermoplastic composites. The objective is to retain the high mechanical properties of the composites and reduce the overall environmental impact at affordable cost.#

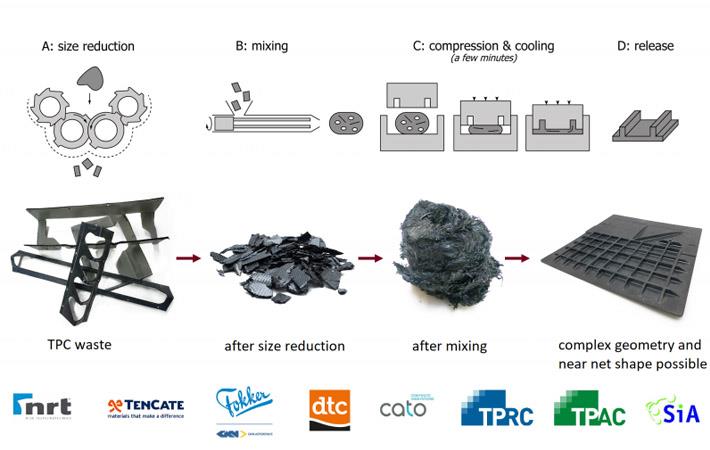

The project includes the process from waste collection to shredding, reprocessing and application. The recycling solution features short cycle times, net-shape manufacturing and enables the production of complex shapes. High mechanical properties are obtained by retaining long fibre lengths.

Research centres Trans-Pacific Aerospace Co (TPAC) and ThermoPlastic composites Research Center (TPRC) have developed a new recycling process that targets the production scrap of thermoplastic composites. The objective is to retain the high mechanical properties of the composites and reduce the overall environmental impact at affordable cost.#

Researchers in this project will work on understanding of the relation between the mechanical properties of recycled material and the transformation of the material during all processing steps. Three demonstrators are currently being developed to show the application in a high value market by an aerospace part and high volume market by a safety shoe nose cap. (PC)

Fibre2Fashion News Desk – India