Besides new sustainable products and customised fresh developments, the focus is on further developing and optimising existing fibre types servicing this important segment. As there is a growing demand for more environmentally friendly products and a necessity for new primary raw materials and solutions, Trevira develops sustainable solutions based on biopolymers like PLA (polylactic acid). This biopolymer is made from plant material and offers many possible applications. Furthermore, PLA is biodegradable under industrial compostable conditions. The company offers mono and bicomponent fibres in PLA. A new offering in biopolymer fibres is a siliconized PLA hollow fibre for use in fillings, Trevira said in a press release.

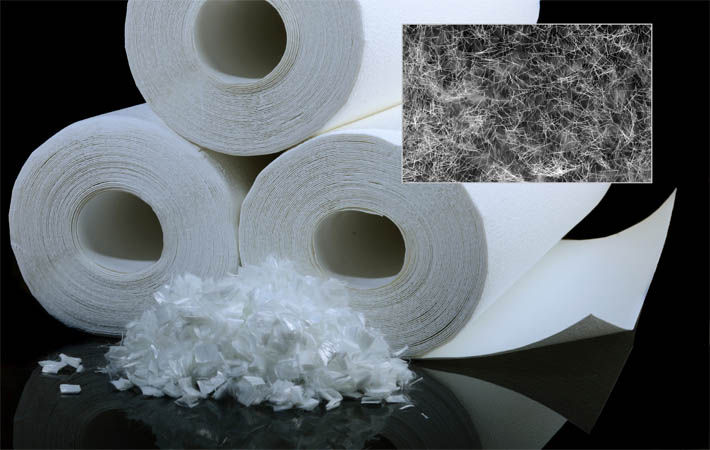

Due to the increased need for fibres with additional functionalities and to the use of fresh combinations of raw materials, capacities in bicomponent fibres have been expanded. Trevira has taken up the challenge and excels at offering bicomponent fibres incorporating not only polyester but also sustainable raw materials like PLA and PBS to develop high-performance fibres and end products in close cooperation with its partners.

A new offering in the portfolio is bicomponent fibres based on PLA and PBS (polybutylene succinate). Both biopolymers offer an exceptional technological opportunity since they have outstanding properties in terms of environmental care and sustainability whilst rendering the required functions. Another approach to more sustainable products is modified virgin and recycled polyester fibres that become biodegradable through an additive solution.

When the fibres go to landfills, they are exposed to moisture, oxygen, and microbes (bacteria). The additive provides little spots within the polymer that the bacteria can attach itself to, and it then starts breaking down the polymer chain. It is basically polymer degradation, which is the reverse process of making the polymer. These biodegradable fibres are available as mono and bicomponent fibres.

The recycling of PET bottles is an important contribution to environmental sustainability. Trevira processes bottle flake regranulate into fibres. The company’s portfolio of fibres from recycled materials contains standard fibres but also fibres with flame retardant or low-pill functionalities. GRS certification has been obtained for these products. New investments are planned at the site at Bobingen to expand capacities for recycled fibres

In response to customer demand in terms of product functions and material properties, the comprehensive product range for air-laid applications is being continuously enhanced. It also applies to special fibres for the carding sector and shortcut types for the paper industry, where the focus is on improving dispersion.

For both, the polyester and the PLA programme, Trevira has also developed modified fibres for the hygiene sector (for example, for wet wipes), where these stand out due to their particularly soft handle. Trevira has the ISEGA certificate for specific fibre types in applications with hot water filtration (coffee and tea filters) as well as packaging materials with food contact. As well as the company’s bicomponent portfolio, all the standard (virgin) and flame retardant fibres are antimony-free.

At Index 2021, Trevira will again participate in a joint presentation with sister companies from the Indorama Ventures parent group, a repeat of the procedure followed at the last events in 2014 and 2017.

Fibre2Fashion News Desk (GK)