German textile machinery firm, Truetzschler, will show high-performance solutions for efficient production of disinfectant and biodegradable wipe materials at SINCE/ANEX 2021 show, in booth 1J20. The 19th Shanghai international nonwovens exhibition (SINCE) and Asia Nonwovens Exhibition and Conference (ANEX), will be held from July 22- 24, 2021, in China.

It’s the classic combination of polyester and viscose fibres which combines exceptional good wipe characteristics with affordable raw material costs. For such high-speed carding/spunlacing processes, Truetzschler Nonwovens offers production line configurations with three roller cards. Such an extended carding section not only enhances web quality but also fully utilises AquaJet’s spunlacing power to deliver up to four tons of nonwovens per hour, the company said in a press release.German textile machinery firm, Truetzschler, will show high-performance solutions for efficient production of disinfectant and biodegradable wipe materials at SINCE/ANEX 2021 show, in booth 1J20. The 19th Shanghai international nonwovens exhibition (SINCE) and Asia Nonwovens Exhibition and Conference (ANEX), will be held from July 22- 24, 2021, in China.#

Truetzschler will also display line concepts for eco-friendly baby and body wipes. The company will also display the Truetzschler‘s proven CP (carded/pulp) nonwoven line concepts with built-in flexibility. The machinery is able to process various pulp types for the wet-laid layer and various fibre types for the carded layer. The outcome is a broad range of CP products optimised for specific requirements. CP lines round up Truetzschler Nonwovens’ solutions for manufacturing sustainable nonwovens. Other displays at SINCE include technologies for pulp-based WLS (wet-laid/spunlaced) nonwovens, cotton nonwovens and nonwovens made from 100 per cent viscose or lyocell fibres.

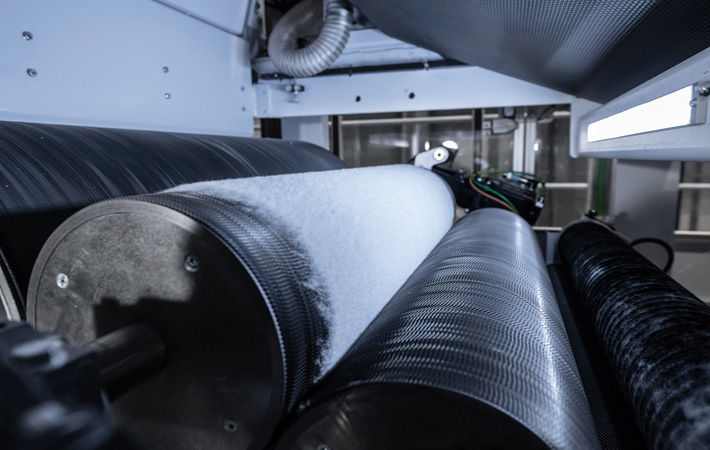

Truetzschler Card Clothing introduces a new generation of condenser wires. Condensing rollers in the card’s doffing section both increase strength in cross direction and the web’s volume but are prone to fibre accumulations. To minimise this risk, the new clothing feature a unique tooth geometry and are manufactured by a special combined surface treatment and hardening process, according to Truetzschler.

The company specialises in machines, systems, and accessories for spinning preparation, nonwovens, and the chemical fibre industry. Truetzschler Nonwovens is a division of the Truetzschler group with a focus on complete production lines and machinery for hydroentangled (spunlaced), through-air and chemical bonded nonwovens. Its range of products includes solutions encompassing the entire nonwovens process chain from fibre preparation, web formation, web bonding, and finishing to drying and winding.

Truetzschler Card Clothing produces high performance clothing for cards and roller cards for the spinning and nonwovens sector. Thanks to the close cooperation within the Truetzschler group, the card wires are tailored to the Truetzschler cards and roller cards. The range of products also includes card wires for machines made by other manufacturers.

Fibre2Fashion News Desk (GK)