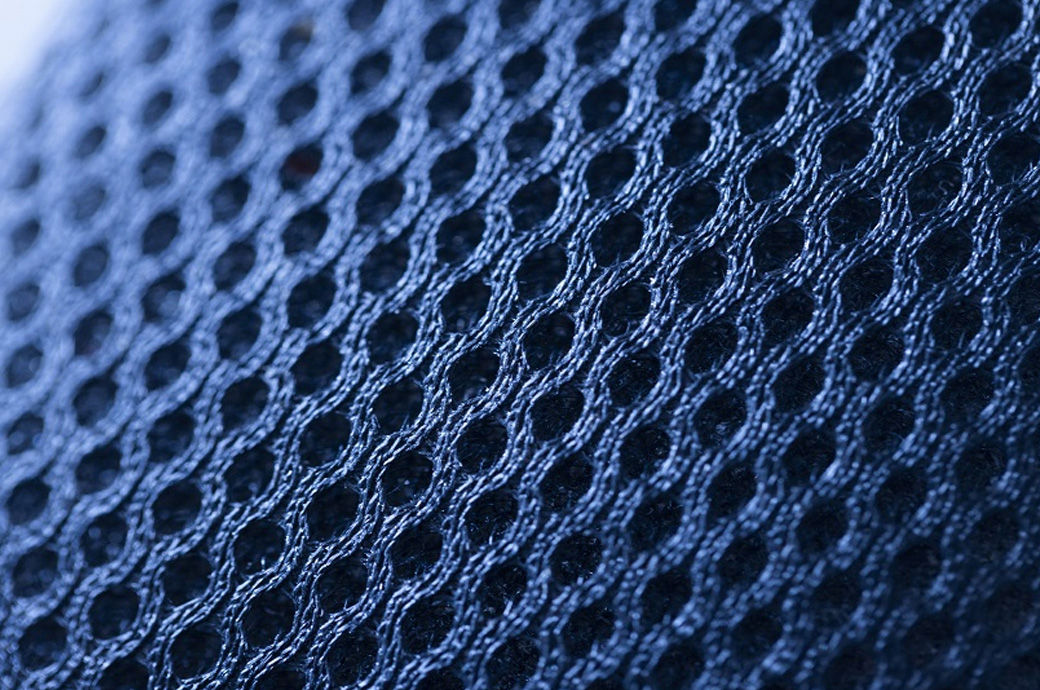

Academics within the University’s Wolfson School of Mechanical, Electrical and Manufacturing Engineering hope their recent technological advancements can help them create clothing that will help measure activity levels and communicate with their surroundings.

Their most recent work has used 3D printing techniques to create a new Triboelectric Nanogenerator (TENG) design – which can then be customised through a series of liquids for the purpose of efficiently extracting energy from movements and for sensing.

Dr Ishara Dharmasena, senior lecturer at Wolfson school, is leading on the project – which is now in the process of using this knowledge to develop wearable technology which picks up on a person’s natural movements to provide health data. “TENGs are a rapidly growing piece of technology which are becoming a leading candidate in developing future smart textile and health monitoring applications. The finding of this study, which provides detailed insights into how these devices can be made more efficient and effective, directly feeds into our efforts to develop technologies such as ‘super-smart textiles’, leading to a promising future with advanced and sustainable wearables,” Dharmasena said.

“During our research, we have found several previously unknown trends in the output of TENGs which help broaden our understanding. The techniques we introduced help to significantly improve the performance of TENG, which can help us make these devices more efficient, smaller, and cheaper. Our target is to use these results to create impactful and affordable practical applications such as wearable health monitoring systems in the near future,” said Rameesh Bulathsinghala, a PhD student contributing to this study.

“One of the key factors for the future success of this technology is to understand and work out how best to design the TENG, so that they can provide us with the best possible electrical performance. Dielectric constant of the TENG – which measures a substance’s ability to store electrical energy within an electric field, is a decisive factor which needs to be engineered during this design process. As there is little knowledge on how the dielectric constant can be tuned to control TENG electrical outputs, understanding the real impact of it within this space has been particularly difficult experimentally, as it is a unique property for a given material,” Dharmasena added.

“Changing the dielectric constant would typically mean changing the material or doing significant modifications, which changes many other properties such as surface area and charge density. This creates a lot of complexity in their design process. However, our findings allow us to alter the dielectric constant without interfering with any of the other properties – it’s a tremendous breakthrough,” he concluded.

Fibre2Fashion News Desk (RR)