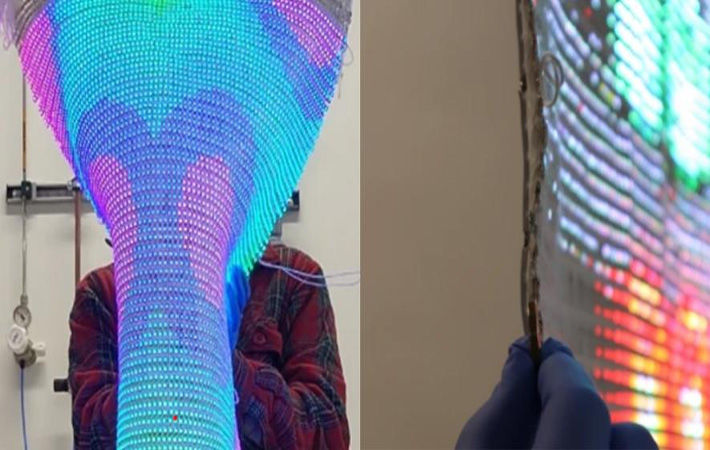

The researchers say that their approach could lead to applications that sound like sci-fi: curtains that are also TVs, energy-harvesting carpets, and interactive, self-powered clothing and fabrics.

This is the first time that a scalable large-area complex system has been integrated into textiles using an entirely fibre-based manufacturing approach. Despite recent progress in the development of smart textiles, their functionality, dimensions and shapes are limited by current manufacturing processes, the University of Cambridge said in a press release.

Integrating specialised fibres into textiles through conventional weaving or knitting processes means they could be incorporated into everyday objects, which opens up a huge range of potential applications. However, to date, the manufacturing of these fibres has been size limited, or the technology has not been compatible with textiles and the weaving process.

“To make the technology compatible with weaving, the researchers coated each fibre component with materials that can withstand enough stretching so they can be used on textile manufacturing equipment. The team also braided some of the fibre-based components to improve their reliability and durability. Finally, they connected multiple fibre components together using conductive adhesives and laser welding techniques,” the release added.

Using these techniques together, the researchers were able to incorporate multiple functionalities into a large piece of woven fabric with standard, scalable textile manufacturing processes. The resulting fabric can operate as a display, monitor various inputs, or store energy for later use. The fabric can detect radio frequency signals, touch, light and temperature. It can also be rolled up, and because it’s made using commercial textile manufacturing techniques, large rolls of functional fabric could be made this way.

The researchers say their prototype display paves the way to next-generation e-textile applications in sectors such as smart and energy-efficient buildings that can generate and store their own energy, Internet of Things (IoT), distributed sensor networks and interactive displays that are flexible and wearable when integrated with fabrics.

“Our approach is built on the convergence of micro and nanotechnology, advanced displays, sensors, energy and technical textile manufacturing,” said professor Jong min Kim, from Cambridge’s department of engineering, who co-led the research with Dr Luigi Occhipinti and professor Manish Chhowalla. “This is a step towards the full exploitation of sustainable, convenient e-fibres and e-textiles in daily applications. And it’s only the beginning.”

“By integrating fibre-based electronics, photonic, sensing and energy functionalities, we can achieve a whole new class of smart devices and systems,” said Occhipinti. “By unleashing the full potential of textile manufacturing, we could soon see smart and energy-autonomous Internet of Things devices that are seamlessly integrated into everyday objects and many other sector applications.”

The researchers are working with European collaborators to make the technology sustainable and usable for everyday objects. They are also working to integrate sustainable materials as fibre components, providing a new class of energy textile systems. Their flexible and functional smart fabric could eventually be made into batteries, supercapacitors, solar panels and other devices.

The research was funded in part by the European Commission and the Engineering and Physical Sciences Research Council (EPSRC), part of UK Research and Innovation (UKRI).

Fibre2Fashion News Desk (RR)