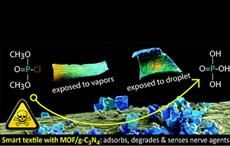

Assembly of intelligent textiles using ultrasonic is coming up as a modern, economical alternative to sewing. PFAFF Industrial has been dealing with this technology for more than 25 years. Intelligent textiles need to be assembled. The individual components have to be combined into a final product such as a piece of clothing using a joining technology.

Traditionally a sewing machine is used to join components of intelligent textiles. Usually intelligent textiles (in leisure, sports outdoor, protective clothing) are also technical textiles.Assembly of intelligent textiles using ultrasonic is coming up as a modern, economical alternative to sewing. PFAFF Industrial has been dealing with this technology for more than 25 years. Intelligent textiles need to be assembled. The individual components have to be combined into a final product such as a piece of clothing using a joining technology.#

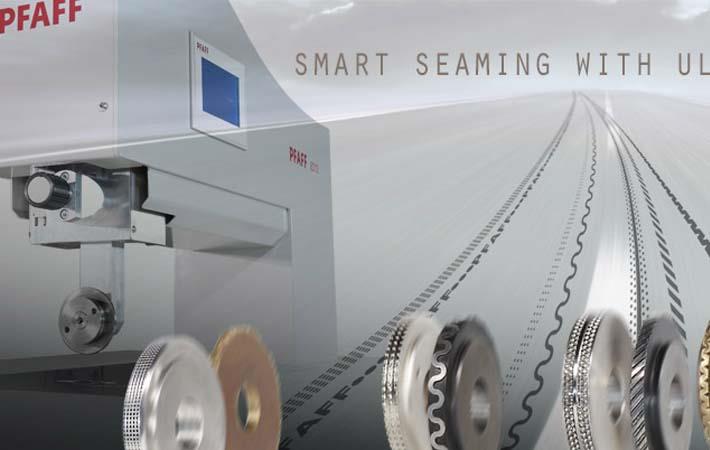

“Ultrasonic welding” has been facilitated by innovations like programmed welding which involves programming of individual and entire seam sections, differential feeding which allows smooth and non-distorted seams or insertion of fullness, and cut and seal which means welding and trimming in one operation.

The process offers several technical advantages - no needle, no thread, no consumables. Additionally, the designer may refer to a multitude of seam designs, because the seam design is specified via the machine's selected anvil wheel. PFAFF offers the customer a wide selection of anvil wheels. At the "customer's request", anvil wheels featuring customised designs can be created.

For the first time ever, a complete piece of clothing (t-shirt) will be assembled using ultrasonic at a tradeshow at the Munich Fabric Start in Munich during September 5-7, 2017. In addition, some weld seams will be "taped" using a PFAFF hot-air taping machine. This welded tape could be used to seal the seam or merely as a design element.

The t-shirt will be produced in full and live together with other innovative partners at the Microfactory special show space. The objective of the Microfactory is to demonstrate to the industry an interlaced solution "from sketch to sewn garment".

The process uses PFAFF-welding solutions to join/assemble - ultrasonic welding machine PFAFF 8312 Dual for joining the closing seams and trimming the edges for example, side seam and shoulder seam, ultrasonic welding machine PFAFF 8312 for hemming operations for example, neckline, arm hole and lower hem, and tape welding machine PFAFF 8303i for taping the closing seams. (SV)

Fibre2Fashion News Desk – India