Initial studies conducted in AFRL’s Materials and Manufacturing Directorate and the 711th Human Performance Wing suggest that qiviut fibres offer superior thermal insulating properties compared to traditional merino wool cold-weather garments. The team aims to create a textile that is lighter, stronger, and more sustainable, according to an AFRL article authored by Gail L Forbes.

“When pilots conduct cold-climate missions in Arctic spaces such as Alaska, they might need to land in water, on frozen tundra, on ice. There are a multitude of possibilities. So, we need a textile that has multiple properties, something that does more than just keep us warm in the event of unplanned isolation,” said Dr. Nancy Kelley-Loughnane, research team lead in the Materials and Manufacturing Directorate’s biomaterials branch.

The researchers are also exploring the possibility of replicating muskox wool keratin fibres using synthetic biology, which would address supply chain issues, bolster US-based textile manufacturing, and promote biotechnology research initiatives.

Dr. Mark Tyler Nelson, research biomedical engineer in the 711th Human Performance Wing, noted that traditional insulating materials such as merino wool and goose down have concerns about practicality and sustainability. The aim is to develop a textile that offers thermal insulation, quick-drying, moisture-wicking properties, and remains lightweight even when wet.

The researchers are also considering ways to keep textile production for military uniforms in the US to reduce dependence on foreign nations. However, sourcing qiviut is expensive due to limited muskoxen populations, thereby necessitating the synthetic approach.

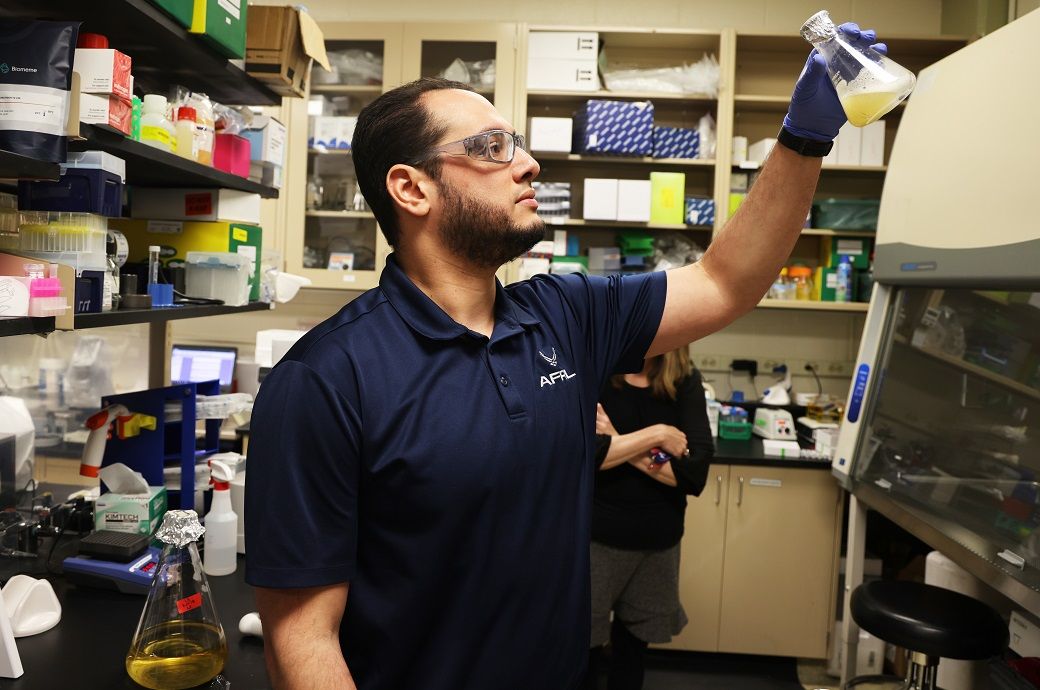

The team is currently focusing on replicating qiviut by expressing muskox fibre proteins in E. coli bacteria. The synthetic material could then be combined with existing polymers such as nylon to create a preferred textile product.

The ultimate goal is to create a next-generation textile that offers superior quality and accessibility and is environmentally friendly. As the research advances, the team aims to partner with the textile industry to scale up keratin protein production.

“I’m a big fan of biology for its complexity. I think that’s probably why we’re all doing this. It’s a field that is just unparalleled in its intricacy. While this research is still in a very early state, what I am most excited about is its potential to inform the next generation of insulative materials that can actually contribute to solving a problem,” said Dr. Pat Dennis, senior research biologist in the biomaterials branch.

Fibre2Fashion News Desk (NB)