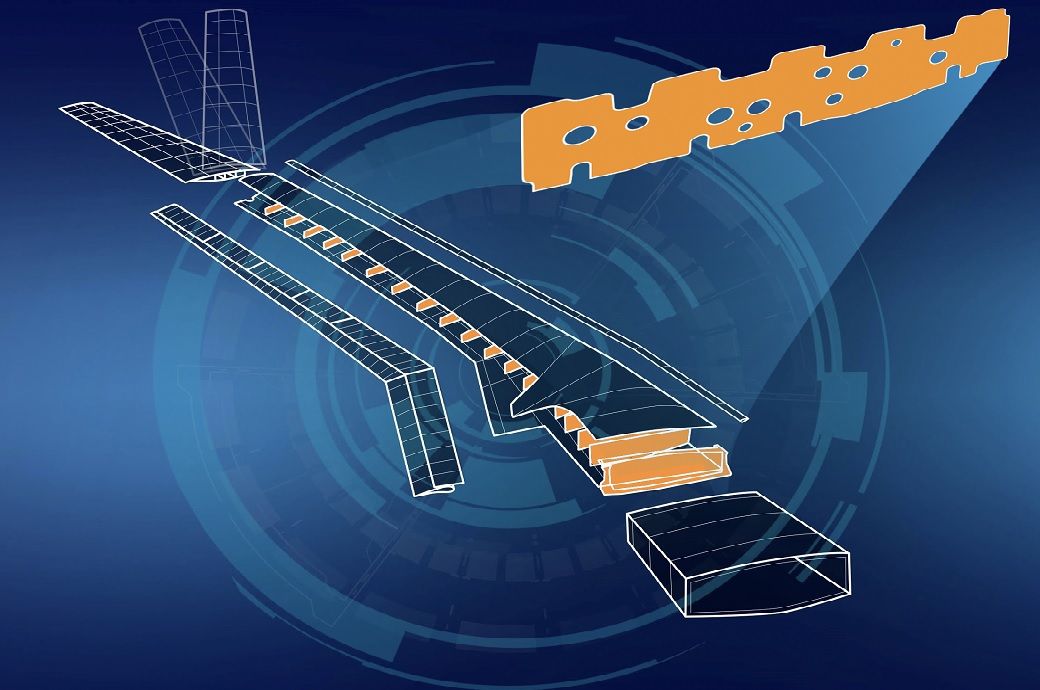

During the last three years, AEC has been collaborating with Airbus on a number of government supported R&D programmes such as the Wing of Tomorrow and Clean Aviation. AEC applied its innovative 3D woven technology to this important wing application, which along with its proven industrialised capabilities in high-rate RTM processing, will produce high tolerance integrated parts such as wing ribs targeting cost / weight / performance benefit in next generation aircraft.

"Advances in digitalisation together with composite manufacturing innovations are demonstrating cost effective and higher-rate with reduced waste and energy consumption to produce next generation sustainable and lightweight composites products,” Brent Stevenson, AEC’s SVP of Research and Technology, said.

“We are proud and excited to be working with Airbus to deliver lightweight and high-performing composite wing components that contribute to the extremely important sustainability goals of the aerospace industry. Developing composite manufacturing technologies capable of reducing factory footprint, capital equipment and production costs while supporting future rate, weight, and performance goals provides an excellent platform to execute our mission to be a partner of choice to the aerospace OEMs and Tier 1s,” Greg Harwell, AEC president, said.

Fibre2Fashion News Desk (RR)