Ascent is showing a 3D printed trim fixture. The fixture was printed using a Thermwood large format additive manufacturing machine, which is located at Ascent’s Santa Ana, CA facility. The tool has an integrated vacuum system with cutter grooves and seals to ensure, when used, the part is held to the tool so it can be accurately trimmed and machined, Ascent said in a media statement.

Sean Henson, the global product manager of composites and additive manufacturing for Ascent, presented in the CAMX Theatre. His presentation included the features and benefits of utilising 3D printed tools, the advantages of using composite materials and the cost savings associated with both.

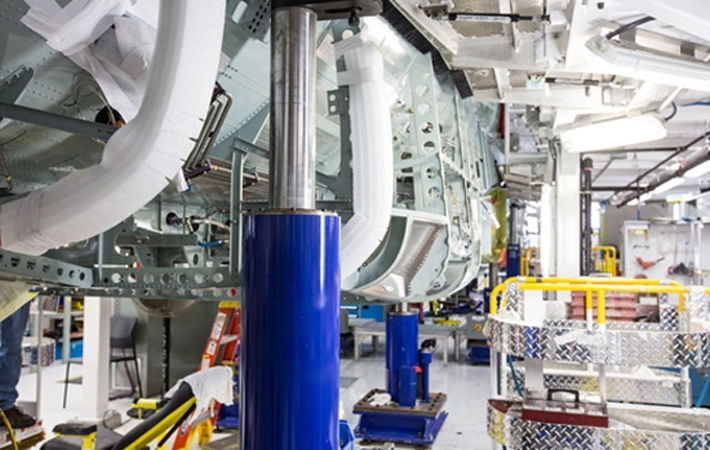

Ascent Aerospace is a world renowned, single-source provider of turnkey production and automated assembly systems for the aerospace, defence, and space industries. Our unique offering consists of a variety of products and solutions to resolve challenging aerostructure assembly requirements, from wing components and fuselage structures to final assembly lines.

As the industry’s largest tooling and automation group, Ascent produces a full suite of composite tooling, including layup moulds, mandrels, bond tools, and trim and drill fixtures, including the largest Invar moulds ever made for aerospace.

In addition, Ascent offers automated, high-precision drilling and fastening systems, having installed more than 2,200 systems globally. As an assembly line integrator, Ascent works with airframers to develop their project and see it through from process design and engineering through build and installation, to ensure it is an efficient and cost-effective solution.

Fibre2Fashion News Desk (GK)