Continuous Composites, a pioneer in the AM 2.0 industry, has earned a Phase II Small Business Innovation Research (SBIR) contract from the Department of Defence. The company will use its patented Continuous Fibre 3D Printing (CF3D) manufacturing process for a DoD multifunctional structural composite application through collaboration with AFRL.

The SBIR topic focuses on attritable structures, engines, and sensors of autonomous unmanned aerial systems and space systems.Continuous Composites, a pioneer in the AM 2.0 industry, has earned a Phase II Small Business Innovation Research (SBIR) contract from the Department of Defence. The company will use its patented Continuous Fibre 3D Printing (CF3D) manufacturing process for a DoD multifunctional structural composite application through collaboration with AFRL.#

Accelerating change while increasing complexity, unpredictability, and mass, a primary objective of the United States Air Force Science and Technology Strategy, is hampered by aerospace composite manufacturing techniques which require significant manufacturing time by a skilled workforce. Continuous Composites’ CF3D technology is an automated manufacturing solution that significantly reduces cost, weight, and lead-time while opening new capabilities for complex structural solutions. Its unique capabilities to introduce low-cost, topology optimised structures directly align with Low-Cost Attritable Aircraft Technology/Platform (LCAAT/P) initiatives.

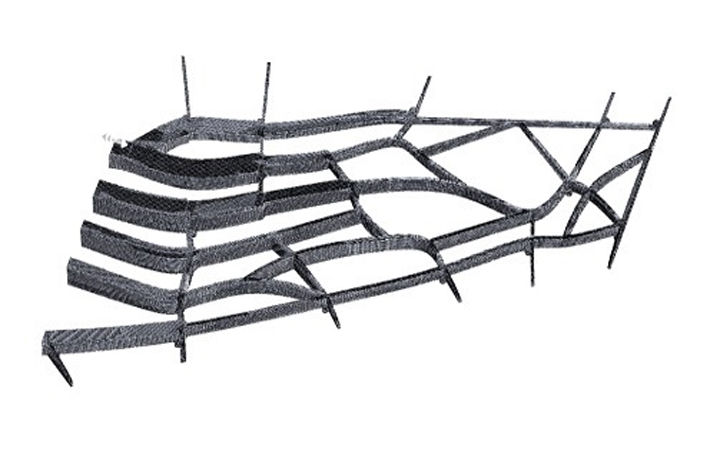

The primary technical objectives of this contract are to fabricate an organically integrated wing spar and rib configuration into a single component, resulting in a completely unitised wing frame. The design for the topology optimised wing structure will be generated using a disruptive AI software solution, Generative Design, in collaboration with the Advanced Structural Concepts division in the Aerospace Systems Directorate of the Air Force Research Laboratory (AFRL). Design inputs include CF3D’s print capabilities combined with the mechanical properties of high-performance thermoset resins and continuous carbon fibre.

The CF3D printed, unitised frame will be assembled with composite wing skins resulting in a full-scale wing structure for an unmanned aircraft. A static wing test will be performed by AFRL to evaluate performance and Continuous Composites will document process data that will be compared to more traditional fabrication and assembly processes.

The contract will leverage CF3D as an automated commercial process providing a responsive solution to unpredictable manufacturing surge requirements within the DoD. This demonstration will showcase the emerging capabilities of CF3D by reimagining aerostructures while using a low-cost, fully automated manufacturing technology to print a monolithic composite component. This application demonstrates CF3D with its advanced material solutions developed in collaboration with their materials partner Arkema.

“A Direct to Phase II programme provides us the opportunity to collaborate with this innovative team and their disruptive manufacturing technology to further develop CF3D’s capabilities for mission readiness,” says Craig Neslen – AFRL/RXMS LCAAT manufacturing lead. “We are committed to evaluating and maturing Continuous Composites’ technology for advanced aerostructures which will enable us to meet the challenging manufacturing demands of the DoD.”

“We are honoured to receive this Phase II SBIR contract directly through the Department of Defence,” says Tyler Alvarado, CEO of Continuous Composites. “The AFRL is a long-standing customer who recognised early the disruptive capabilities of CF3D. Through this contract and others, we are committed to transforming DoD Operational Capabilities.”

Fibre2Fashion News Desk (SV)