“We listened to customers and heard their feedback,” said Elsner CEO Bert Elsner. “Sometimes wider is better. The newest 48-wide machine achieves more product throughput at higher speeds without sacrificing adaptability and versatility. We know it will significantly impact the productivity of our customers.”

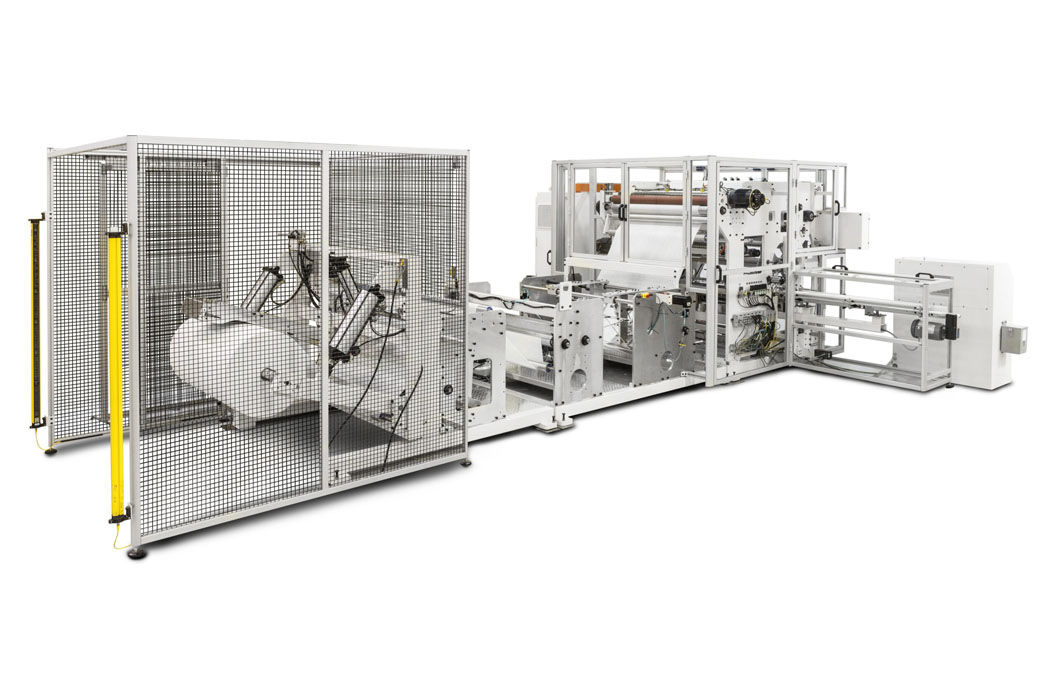

The new ENR can load up to a 48-inch substrate and is engineered to provide over a 14 per cent increase in product output compared to Elsner’s ENR-G3 42 wide machine in the same amount of time. This leap in productivity will allow manufacturers to meet the demand for wipes while optimising their production processes. All while providing the same versatility and quick changeovers available in all Elsner machinery.

With the ENR-G3-48, manufacturers can load 14 per cent more material and produce 14 per cent more product, making it the ultimate solution to meet the ever-growing market demands without compromising quality, the company said in a press release.

At recently tested speeds up to 800 feet per minute, the ENR-G3-48 can produce an impressive 128 rolls per minute of the industry-standard 75-sheet count (6″ x 8″) canister wipes. This accelerated production rate empowers manufacturers to meet high demand efficiently.

Elsner, a trusted name in the industry, has engineered the ENR to ensure precision, consistency, and reliability in wipes production. The ENR is equipped with an intuitive user interface that streamlines operation and minimises the learning curve for machine operators. This machine is designed with durability in mind, ensuring a long and productive lifespan.

Elsner Engineering has a heritage of manufacturing purpose built precision solutions for industries worldwide. The newest ENR-G3 is a testament to our dedication to excellence, offering businesses innovative tools to enhance their production capabilities.

Fibre2Fashion News Desk (RR)