HexTow IM9 24K is an intermediate modulus (IM) fibre of 24,000 filaments with an average tow tensile strength over 6,300 megapascals (MPa), a modulus of 298 gigapascals (GPa) and strain of 1.9 per cent. This new product provides a 12 per cent improvement in tensile strength over the Hexcel baseline IM7 fibre, which is a major component in commercial aircraft engine fan blades and other aerospace applications, the company said in a press release.

“Hexcel developed HexTow IM9 24K to be a workhorse fibre that builds on the company’s proven legacy of intermediate modulus fibres,” said Imad Atallah, vice president, product management, Composite Materials. “We are excited to offer our customers a dependable carbon fibre solution for high-rate manufacturing and high-performance material designs.”

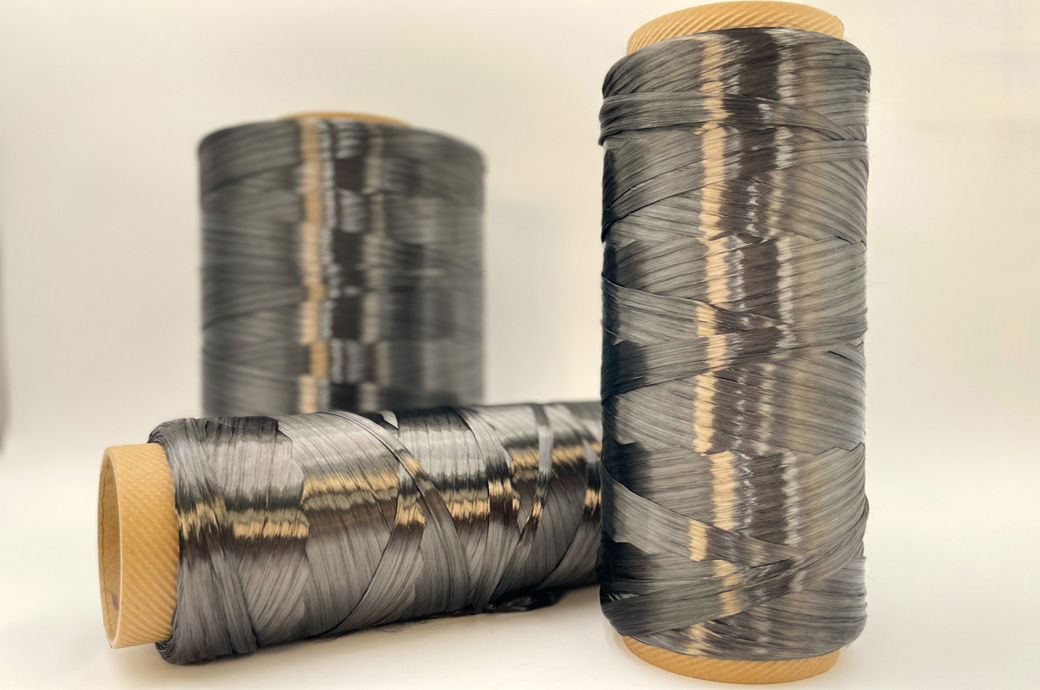

The HexTow IM9 24K provides an alternative solution for customers seeking affordable, high-value composites, and is particularly suited for manufacturing primary and secondary aerospace vehicle structures. The combination of the fibre’s high performance and translation into composite tensile strength, as well as the increased fibre line throughput and productivity provided by a 24K tow size, provides a strong value proposition when compared to other commercially available IM fibres.

With the launch of the new HexTow IM9 24K carbon fibre, Hexcel anticipates qualifying the product with highly-toughened epoxies, thermosetting bismaleimide (BMI), out of autoclave (OOA) and other high performance resin systems. Composite data is currently being generated in a variety of resin systems and will be made available to customers.

Fibre2Fashion News Desk (RR)