Billions of petroleum-based synthetic disposable surgical masks are discarded globally on an annual basis. Increasingly, governments and consumers are recognising the environmental threats posed worldwide by this plastic pollution. Most disposable Personal Protective Equipment (PPE) consists of petroleum based, non-biodegradable polymers that can take up to 450 years to decompose in our landfills, rivers, lakes, and other natural environments, PADM Medical said in a press release.

PADM Medical’s Precision Eco Plant Based procedural masks are made using Ecofuse plant-based materials manufactured by PADM Medical's sister company, Roswell Textiles, in Calgary, Alberta. Ecofuse materials are manufactured from renewable crop resources and help reduce the adverse impact on the environment of petroleum-based, single use disposable face masks. The Ecofuse materials are industrially compostable and by being plant-based, help reduce the CO2 emissions of Precision Eco by approximately 55 per cent compared to conventional petroleum-based masks. Precision Eco procedural masks also generate carbon credits as a result of the net carbon reduction.

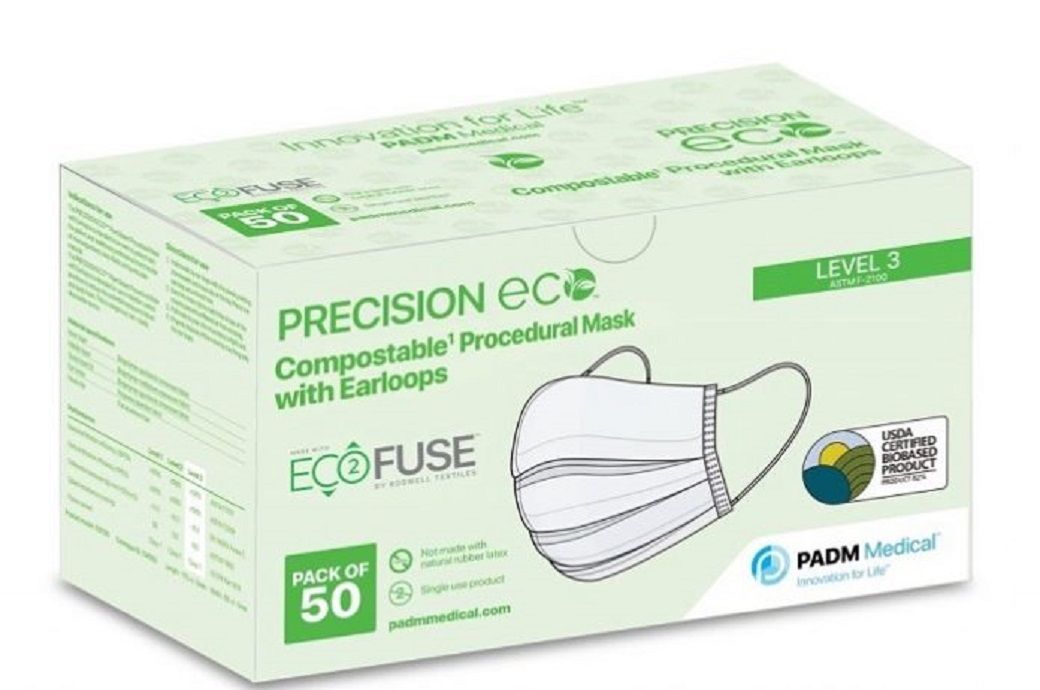

Additionally, the Precision Eco Compostable/Plant Based Procedural Mask with Earloops is a USDA certified biobased product under the USDA BioPreferred Program with a biobased content of 82 per cent.

“The 510(k) Clearance on the 82 per cent plant-based Precision Eco product is a tremendous milestone, not only for PADM Medical, but also for the healthcare industry and our planet,” said Martin Petrak, PADM Medical Group CEO. “For the first time ever, the US healthcare system now has a plant-based medical grade face mask alternative that provides the same level of protection as a traditional synthetic plastic product. Our Precision Eco mask achieves a net 55 per cent reduction in carbon emissions and minimises the larger environmental damage caused from the millions of tonnes of synthetic plastic medical waste that is generated on an annual basis by traditional face masks. It is this commitment to our planet that drives us as a company as we continue to innovate for a greener and more sustainable world.”

“The FDA 510(k) clearance is the highest level of validation available for the use of Ecofuse materials in one of the strictest regulatory environments possible—healthcare,” said Kyle Fiolka, president of Roswell Textiles and chief innovation officer for the PADM Group. “Roswell Textiles’ Ecofuse materials are allowing manufacturers to reduce the carbon footprint of their existing product lines, without sacrificing performance or technical standards. We are honoured to have worked alongside PADM Medical as they pursued this momentous achievement. This opens the doors to Ecofuse materials becoming the new standard plant-based material for healthcare single use disposables like gowns, drapes, sheets, wraps, etc. If a hospital could reduce their carbon emissions by up to 55 per cent per product line as a result of a more sustainable supply chain decision, why wouldn’t they do that?”

Fibre2Fashion News Desk (NB)