SEMI-FlexTech, a consortium working to advance manufacturing of printed flexible electronics, has awarded $9.2 million in federal funds from a cooperative agreement with the Army Research Laboratory for development of the glove. The Massachusetts Manufacturing Innovation Initiative (M2I2), a state effort to advance manufacturing innovations and job growth through industry-academic collaborations, has awarded an additional $8.4 million for the purchase of equipment at WPI and UMass Lowell that will be used to produce and test a prototype glove, WPI said in a press release.

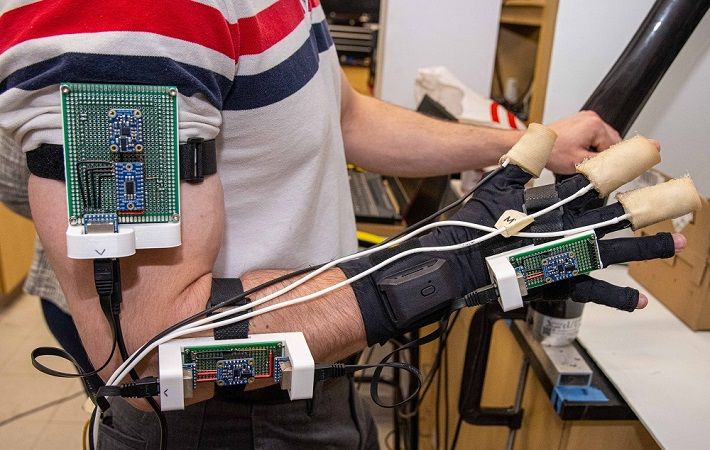

Rao, an associate professor in the Department of Mechanical and Materials Engineering and principal investigator (PI) on the grants, said researchers will produce a prototype glove within 18 months. The glove will be flexible and washable, with integrated circuits printed onto stretchable fabric. Inflatable pockets around the fingers will fill with air to give a user feedback and the sensation of grasping an object, and the glove will be powered with a battery that sits in the pocket of a garment worn by the user.

“A fully integrated glove that allows a human to operate or train a robotic system could be used in advanced manufacturing settings, warehouses, remote health care, hazardous situations, and other applications,” said Rao. “In addition, the production methods and wearable technologies we develop will benefit Massachusetts by expanding the state’s manufacturing capabilities and the expertise of Massachusetts workers.”

The project builds on a glove designed by Onal, associate professor in the Department of Robotics Engineering. Onal and Li, who is an assistant professor in the Department of Robotics Engineering, are co-PIs on the SEMI-FlexTech and M2I2 grants. In addition, all three WPI professors are training graduate students in interdisciplinary research through WPI’s National Science Foundation Future of Robots in the Workplace–Research and Development (FORW-RD NRT) programme, which is led by Onal.

“The glove we develop will allow humans to better collaborate with robots,” Cagdas Onal, professor in the department of Robotics Engineering, said. “Users wearing the glove will be able to train robotic equipment how to move. In other applications, humans may learn a task by training on robotic equipment.”

The researchers will use the SEMI-FlexTech funding to develop a glove and the software to control it. M2I2 funds will go to purchase manufacturing equipment that will be housed at the university’s Lab for Education and Application Prototypes (LEAP) and testing equipment that will housed at the FORW-RD NRT collaborative space. The researchers will use the equipment to print integrated circuits onto a glove and bond microchips and other components onto the circuitry, and to test the glove with a mobile robotic arm, eye-tracking goggles, and a virtual reality system, the release added.

M2I2 previously awarded $4 million to WPI for the development of LEAP, and the new M2I2 grant comes from state funding for projects that support NextFlex and Advanced Robotics for Manufacturing, initiatives that are part of a national network of Manufacturing USA Institutes. NextFlex also supported WPI’s past research that led to advances in inkjet printing for flexible electronics.

“Through the M2I2 programme, the commonwealth has committed over $100 million to boost innovative projects across the commonwealth that will enhance the competitiveness of our advanced manufacturing sector,” said Christine Nolan, director of the Westborough-based Centre for Advanced Manufacturing at MassTech, which manages the M2I2 programme. “This project brings together two of our leading universities when it comes to innovation in manufacturing, WPI and UMass Lowell, which have partnered on several other projects. Their development of this interactive glove could have material impacts to the manufacturing sector, but also in healthcare, defense, and consumer products like digital games. There’s a huge potential.”

“This new project is a great example of synergies among manufacturing institutes that are leading to additional funding avenues, cross-team interactions, and the expanded impact of WPI’s investments in LEAP,” said Ellen Piccioli, WPI's director of manufacturing innovation. “Projects such as these leverage WPI’s strengths in advanced materials, manufacturing, robotics, and artificial intelligence. These projects also align with M2I2’s goals around advancing innovation and job growth through academia-industry-government collaborations.”

“UMass Lowell is excited to have our researchers—Plastics Engineering professor Joey Mead, Research Scientist Jinde Zhang, Plastics Engineering assistant professor Jay Park, and Mechanical Engineering associate professor Chris Hansen—as part of this collaborative project with WPI. The project leverages our expertise in stretchable materials, soft robotics, and advanced manufacturing processes, to complement our WPI colleagues’ expertise. This is a great example of how partnering among our academic research institutions in the region can lead to new innovations with important societal impact. We are extremely grateful to the state (through M2I2) and to SEMI-FlexTech for their support,” said UMass Lowell’s Julie Chen, vice chancellor for research and economic development.

Fibre2Fashion News Desk (RR)