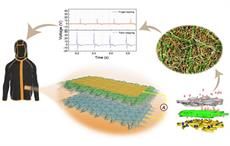

“If you’ve held your smartphone or charge card close to a reader to pay for a purchase, you have taken advantage of near-field signalling technologies. Our fabrics work on the same principle, but we’ve extended the range significantly,” said co-author Peter Tseng, UCI assistant professor of electrical engineering & computer science. “This means you could potentially keep your phone in your pocket, and just by brushing your body against other textiles or readers, power and information can be transferred to and from your device.”

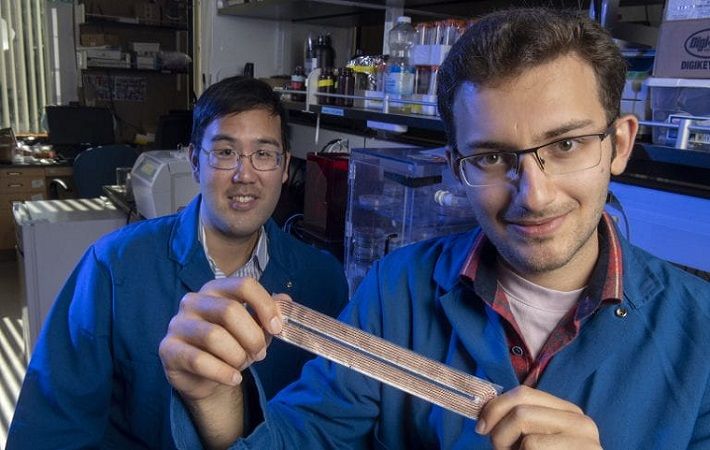

“The invention enables wearers to digitally interact with nearby electronic devices and make secure payments with a single touch or swipe of a sleeve,” said lead author Amirhossein Hajiaghajani, a UCI PhD student in electrical engineering & computer science.

“With our fabric, electronics establish signalling as soon as you hover your clothes over a wireless reader, so you can share information with a simple high-five or handshake. You would no longer need to manually unlock your car with a key or separate wireless device, and your body would become the badge to open facility gates,” Hajiaghajani said.

The near-field communications protocol has enabled the growth in applications such as wireless device charging and powering of battery-free sensors, but a drawback of NFC has been its limited range of only a couple of inches, UCI said in its press release.

The team’s innovation was designed to be highly flexible and tolerant of bodily motion. Because signals travel in the UCI-invented system via magnetic induction – versus the continuous hard-wire connections that had been state-of-the-art in smart fabrics – it’s possible to coordinate separate pieces of clothing. In athletic gear, pants can measure leg movements while communicating with tops that track heart rate and other stats.

The applications in medicine are countless, Hajiaghajani said, such as freeing hospital staff from the task of applying numerous patient sensors, as they can all be integrated into metamaterial-equipped gowns. The materials involved in the system are low-cost and easy to fabricate and customize, he noted, and varying lengths and branches of the metamaterial ‘rails’ can be heat-pressed onto wearers’ existing clothing – no need to go out and buy a brand-new high-tech tracksuit.

“Our textiles are simple to make and can be integrated with interesting wearable designs,” Hajiaghajani said. “We want to create designs that not only are cool and inexpensive but can reduce the burden that modern electronics can bring to our lives.”

Fibre2Fashion News Desk (RR)