NIAR’s Advanced Technologies Laboratory for Aerospace Systems (ATLAS) has begun manufacturing test panels using Victrex AE250 PAEK (polyaryletherketone), a thermoplastic material system reinforced with IM7 carbon fibres. This is a part of the Modeling for Affordable Sustainable Composites (MASC) programme, sponsored by the Air Force Research Laboratory. MASC focuses on developing a certification framework for enabling novel materials and advanced structural concepts used for automated manufacturing technologies. It is the first time a programme has conducted an in-depth investigation into the variability of multiple AFP machines on the composite allowables generated using industry-standard statistical procedures outlined in Composite Materials Handbook 17, according to a press release by the university.

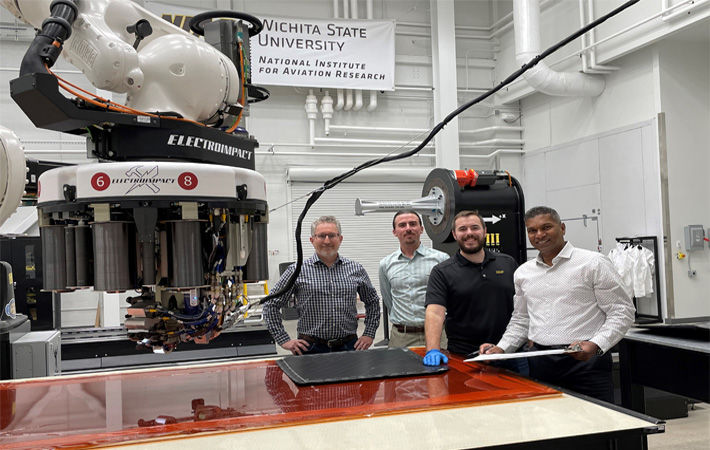

The project includes qualification of several thermoset, thermoplastic and dry-fibre AFP material systems from Hexcel, Solvay, Toray, and Victrex. All of the data and associated documents will be included in the NCAMP shared material database. In order to mitigate risks due to machine variability, a series of pre-qualification manufacturing trials were conducted to develop machine programming protocols to manufacture equivalent panels across various AFP machines. These machine agnostic allowables can then be used by a wide variety of certification programmes regardless of the type of AFP machines used for production. The AFP panel manufacturing kick-off was witnessed by NCAMP airworthiness representatives and personnel from the Air Force Research Laboratory and Victrex.

Fibre2Fashion News Desk (GK)