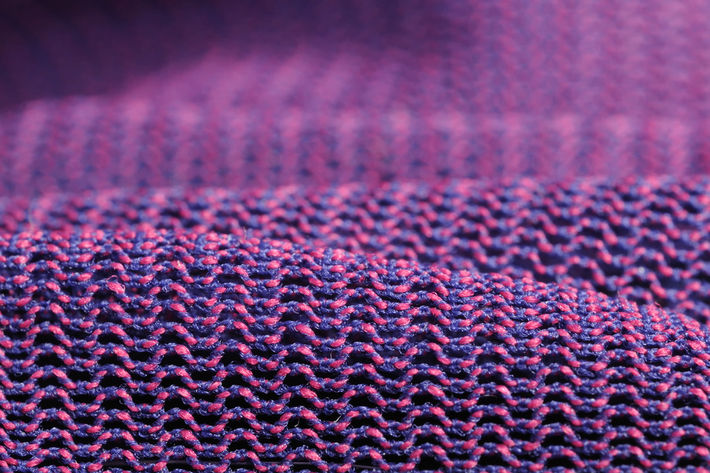

These polymer-based textiles have been widely adopted for their cost-effectiveness and durability, and are found in carpeting, upholstery and filtration products. Many of the applications, particularly transportation interiors and home furnishings, are regulated by strict flammability standards and often employ flame retardants suspected of being toxic to human health and the environment. Recently, the EU took steps to ban up to 12,000 toxic substances, including flame retardant chemicals, driving the demand for eco-friendly alternatives like Retacell, the company said in a media release.

“We are pleased with the progress our team has made in developing textile applications for Retacell. In initial tests, Retacell has been successfully applied to the polymeric material in the finishing process as a surface treatment spray. We will be presenting these results to a global textile manufacturer to ensure that the modified material meets their performance specifications as they phase out toxic flame retardants. The next technological iteration will be creating a Retacell bulk additive that can be incorporated during compounding, potentially reducing the overall manufacturing costs,” commented Keith Duffy, CEO of Xeriant.

Fibre2Fashion News Desk (KD)