Web Industries, a precision converter and contract manufacturing organisation (CMO), is supporting developers of COVID-19 lateral flow immunoassay (LFI) diagnostic tests by awarding production capacity at its Holliston, Mass, plant. LFI tests are under research as health experts seek solutions to efficiently test large numbers of people for COVID-19.

Web’s Lateral Flow Diagnostic Centre of Excellence, a 6,500-square-foot facility built specifically for LFI manufacturing, offers CMO services such as automated reel-to-reel medical device production, in-house biochemistry lab, reagent deposition, LFI strip manufacturing, and device assembly and packaging.Web Industries, a precision converter and contract manufacturing organisation (CMO), is supporting developers of COVID-19 lateral flow immunoassay (LFI) diagnostic tests by awarding production capacity at its Holliston, Mass, plant. LFI tests are under research as health experts seek solutions to efficiently test large numbers of people for COVID-19.#

Web Industries’ medical team has devised processes to help LFI device manufacturers expedite the transition from the research lab to large-volume reel-to-reel production of millions of tests. Web has an LFI economic and manufacturing model available to share with device developers, academic researchers and companies responding to US market needs for COVID-19 test kits.

“As the medical community mobilises in response to ongoing COVID-19 outbreaks, rapid diagnostics will play an increasingly crucial role in slowing the spread of the disease,” said Kevin Young, Web Industries vice president of corporate development. “As an independent US manufacturing partner, we’re ready to play our part in responding to the COVID-19 crisis.”

Web Industries’ US-based manufacturing operations are a critical component of its overall value proposition. “Our LFI manufacturing plant is ready to work on a priority basis to be part of the solution,” Young said. “We can help LFI device developers to efficiently scale up production after they discover a viable LFI solution.”

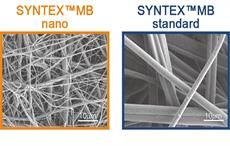

Web Industries also said that it was prepared to develop nonwoven and material converting solutions. It is offering production capacity to support the manufacture of disposable medical products for the COVID-19 crisis. Converting is an important step in the supply chain in which materials are formatted so that they can be run more efficiently on automated manufacturing lines.

Certified under ISO 14001 and ISO 9001, Web has multi-colour, high-speed printing, slitting and traverse winding, or spooling, lines at its factory in Fort Wayne, Ind, the company’s Centre of Excellence for converting personal and home care products. The recently expanded facility has state-of-the-art equipment for converting nonwoven materials. Web’s team is available to discuss how it can support manufacturers of personal protective equipment (PPE) and other medical consumables. Most disposable PPE products, such as surgical masks and protective gowns, are made of nonwoven materials.

Currently, Web converts ties and bindings for surgical masks at the Fort Wayne facility, which predominantly processes nonwoven materials for diapers and other personal and home care products.

“We are available to discuss how we can use our converting lines and expertise to help manufacturers meet demand for disposable medical products needed for the COVID-19 response,” said Adrienne Green, director of sales, personal and home care. “Our engineers are skilled at devising solutions for working with a wide variety of materials and converting them into formats that can be efficiently and seamlessly integrated into the end-product manufacturer’s operations.”

Fibre2Fashion News Desk (SV)