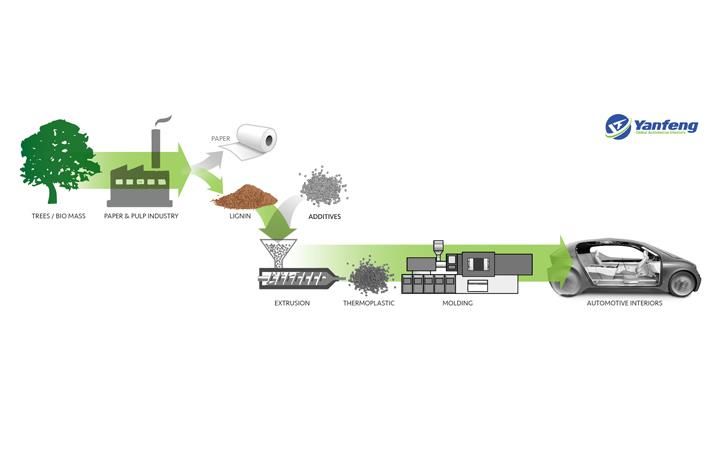

Prisma’s Biolan material is produced using lignin, a natural by-product of the pulp and paper making process. Lignin is essentially the ‘glue’ that surrounds the cell walls of living plants like trees and grasses. It contains a vast amount of the world’s carbon and has the potential, if modified correctly, to replace many of the petrochemical-based products we use in everyday life, said YFAI in a pres release.

Through Prisma’s lignin technology, petrochemicals are partially replaced by natural polymers. The resulting Biolan material improves key properties of traditional ABS plastic, including cost, higher UV resistance, and higher tensile strength while reducing total greenhouse gas emissions.

“YFAI continually looks outside of the industry for materials that not only have applicability for use in automotive interiors, but also are beneficial from a sustainability perspective,” said Jeff Stout, executive director, innovation and new mobility, North America, for YFAI. “We see great promise in the Biolan material.”

“Prisma and YFAI’s agreement is an important step forward in environmental stewardship and is one of the first of its kind regarding this application for lignin,” said Adam McCall, founder and CEO, Prisma Renewable Composites. “For decades, it has been the dream of many scientists to find a higher value purpose for lignin, due to its incredible potential.”

YFAI is the global leader in automotive interiors. It designs, develops and manufactures interior components for all automakers.

Prisma Renewable Composites is a biomaterials company creating technologies to produce high value composite materials, including carbon fibres and polymers, all of which contain lignin, a highly renewable organic polymer. (PC)

Fibre2Fashion News Desk – India