“In Industry 4.0 in general and processing composites in particular, an unencumbered flow of data is the key to workflow efficiency. With Zund PreCut Centre, the user is well-equipped to handle the challenges of demanding manufacturing processes. The software automatically optimizes contours and adjusts cut paths depending on the material and choice of tools. With the integrated nesting function, parts are laid out automatically for optimal material utilisation. Considering the high cost of materials, maximum yield is essential for economical digital cutting,” Zund said in a press release.

With Pick&Place, Zund will present a cost-effective solution for fully automated picking and kitting of cut parts. The Pick&Place interface enables direct communication with the robot via Zünd Cut Center – ZCC, the Zünd operating software and user interface. Pick&Place makes it possible to completely automate parts removal, kitting and placing. The necessary parameters are derived from the metadata supplied with the job order.

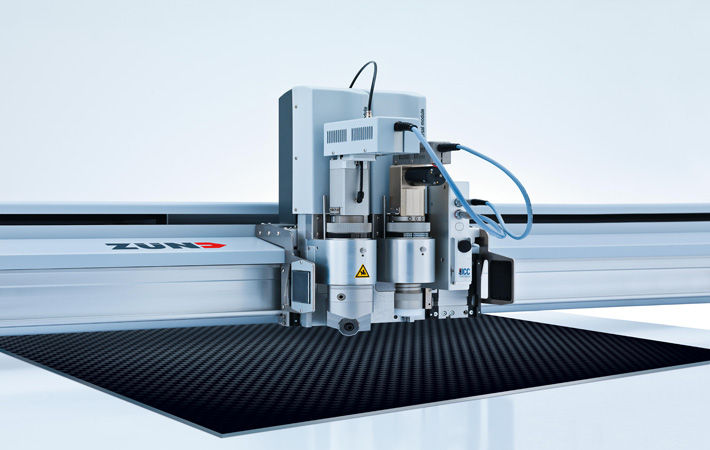

Zund is the cutting system of choice in the automotive and aerospace sector. Capable of delivering the utmost in cut quality and performance, Zund cutting systems are systematically geared towards fully automated digital production workflows; even so, they allow for gradual implementation with a wide array of semi-automated solutions.

“Carbon or glass fibre, semi-finished products such as prepreg or thermoplastic organo sheets, honeycomb, rigid foam core, and auxiliary materials are all part of the wide variety of materials used in the composites industry. The fact that they can all be cut on a single, multi-functional system from Zund makes Zund cutting solutions truly unique,” the release added.

Fibre2Fashion News Desk (RR)