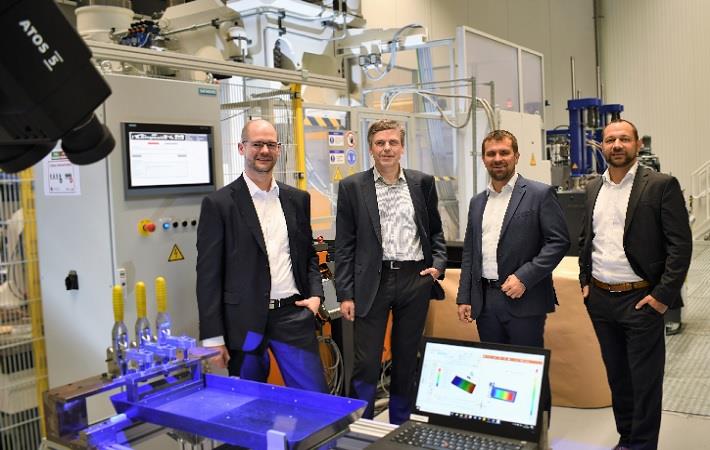

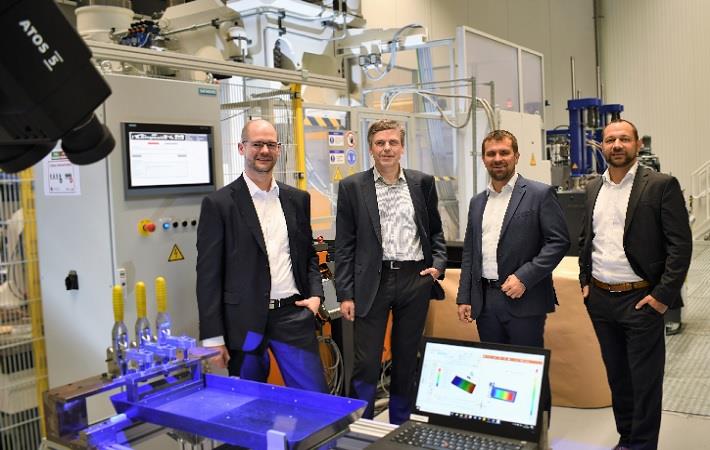

(from L-R) Dr. Michael Emonts, Warden Schijve, Philipp Fröhlig & Dr. Kai Fischer at AZL Tech Center. Pic: AZL

Warden Schijve, former chief scientist composites at Sabic, has become part of the AZL engineering team. Schijve has 35 years of experience in the composites industry. Besides Sabic, he has worked with companies like Fokker and DSM, bringing a broad and deep expertise in structural design, plastics and composites, and processing technology to AZL Aachen.

As design leader, he is expanding the product and application development division of the service provider for business development and technology development in lightweight.Warden Schijve, former chief scientist composites at Sabic, has become part of the AZL engineering team. Schijve has 35 years of experience in the composites industry. Besides Sabic, he has worked with companies like Fokker and DSM, bringing a broad and deep expertise in structural design, plastics and composites, and processing technology to AZL Aachen.#

AZL Aachen supports companies along the entire value chain in implementing competitive lightweight technologies. “We develop component and production concepts for companies, including the analysis of costs and production-relevant KPIs. With our broad range of material and production technologies, we provide a comprehensive solution for the development and evaluation of products and identify the most suitable paths to implementation. Warden Schijve will use his many years of experience to support our partners in the efficient development, evaluation and implementation right up to market readiness,” says Dr. Kai Fischer, managing partner of AZL Aachen.

From his 35 years in the composites industry with Fokker, DSM and Sabic, Schijve brings a broad and deep expertise in structural design, plastics and composites, and processing technology.

Schijve says: “In my career I’ve always seen that it pays off to evaluate various different design concepts, which may use different materials or material combinations, to finally come to the most cost-competitive lightweight applications. Taking into account different manufacturing technologies right from the beginning can save a lot in later stages of component development. And this is what fascinates me about AZL and its eco-system: the available knowledge on a wide variation of process and production technologies, including cutting edge equipment, at both the AZL Tech Centre, and the various institutes present in the total RWTH Aachen Campus.”

Dr. Michael Emonts, managing partner of AZL Aachen, says: “We are delighted that Warden Schijve, as a well-known face from the AZL community, will enrich us in developing lightweight applications, production systems and processes, identifying competitive technology optimisations through the analysis of markets and applications, and supporting our customers in the industrial implementation of the developed technologies.”

Schijve will also lead the project for a concept study for future battery casings based on composite-based multi-material systems. The AZL started the project in October together with 30 participating companies from the entire value chain to get an overview of existing component solutions, evaluate the advantages of a multi-material approach and develop a multi-material component design including a production concept for battery casings.

Schijve together with other design experts will share insights and experiences on composite design tools and methods in a Lightweight TechTalk by AZL on “Best Practises in Lightweight Design” on January 28, 2021.

Fibre2Fashion News Desk (SV)