BASF said it will launch a new binder, Acrodur Power 2750 X, designed for the production of natural fibre composites for automotive lightweight applications such as interior car door panels or shelves.

“As a low-emission alternative to formaldehyde-based reactive resins, Acrodur Power 2750 X gives natural fibres composites high mechanical stability, a BASF press release informed.BASF said it will launch a new binder, Acrodur Power 2750 X, designed for the production of natural fibre composites for automotive lightweight#

“At the same time, the product offers thermoplastic processability and, unlike traditional thermoplastic binders based on PP, it allows the use of up to 75 per cent natural fibres in lightweight components,” BASF said.

At the JEC Composites Show, BASF is going to present at its booth F51 in hall 7.2, a functionalised natural fibre lightweight composite based on Acrodur Power 2750 X.

“Due to the use of Acrodur Power 2750 X, natural fibre components are up to 40 per cent lighter than conventional plastic products,” Claus Dallner, head of marketing for Dispersions for Fibre Bonding at BASF said.

“This results in cars that consume less fuel and have fewer carbon emissions,” he explained.

The water-based binder Acrodur Power 2750 X is a health-compatible alternative to conventional formaldehyde-based reactive resins as it does not release any organic substances.

“This offers greater safety at work for the user, who no longer needs to invest in exhaust air treatment systems and in addition, the binder helps to improve the ambient air quality inside cars,” the specialty chemicals maker observed.

Natural fibres bonded with Acrodur Power 2750 X can be processed using traditional thermoplastic cold-forming methods and be combined in one single process step with complex plastic elements.

The product helps to save both system and process costs and it combines these benefits with great mechanical component stability with the pre-impregnated natural fibres boasting a long shelf-life.

Vice president Jürgen Pfister said, “As a strong development partner in the value chain, equipped with a comprehensive portfolio and technical expertise, we help customers to differentiate from their competitors.”

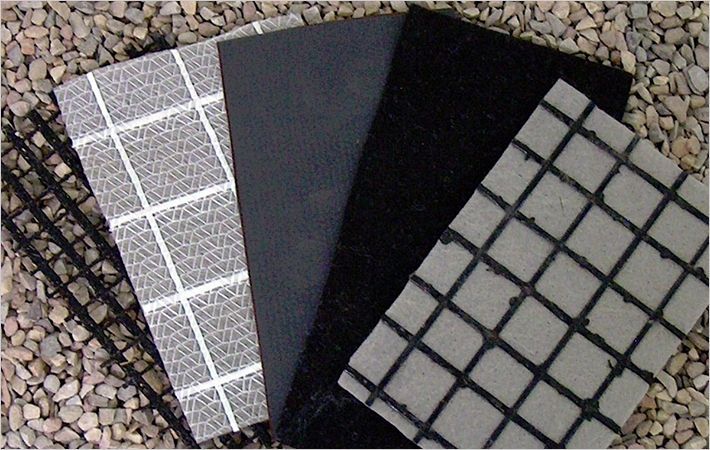

The low-emission Acrodur binders are used to reinforce natural fibre composites before these can be processed into moulded components.

They are also used for the production of high quality lightweight applications in the furniture and automotive industry.

Due to their 3D plasticity, the binders help create attractive design options with a natural fibre look and feel. (AR)

Fibre2fashion News Desk - India