Bindatex Advanced Materials Cutting, which specialises in precision cutting of 'difficult to cut' materials, is enhancing capacity for slitting nonwovens as it continues to deliver fast turnaround times. The expansion follows the successful completion of projects for several UK PPE manufacturers and other companies in the medical technology sector.

The company says it can put enquiries into production within two days if required, compared to the industry norm of weeks.Bindatex Advanced Materials Cutting, which specialises in precision cutting of 'difficult to cut' materials, is enhancing capacity for slitting nonwovens as it continues to deliver fast turnaround times. The expansion follows the successful completion of projects for several UK PPE manufacturers and other companies in the medical technology sector.#

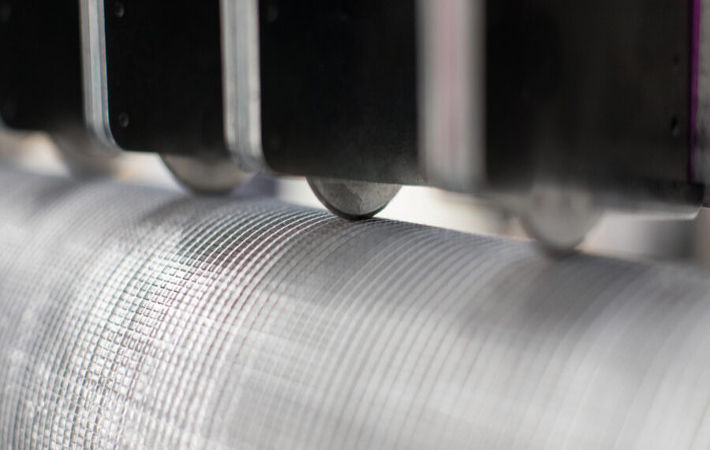

“As cutting specialists, we easily achieve the narrow slitting widths that can be required by the nonwovens industry. We commonly slit to 20mm and readily deliver narrower on request. We can also repackage to very large diameters helping to improve your production efficiencies,” the company said.

“Uneven tension in winding rolls can be a common problem. Not with Bindatex Slitting and Sheeting. We have resolved this issue and enabled material salvage,” it said.

The company’s nonwoven slitting capacity expansion follows the successful completion of projects for several UK PPE manufacturers and other companies in the medical technology sector as well as supporting a range of nonwovens applications across numerous sectors from cosmetics to civil engineering. It has also supplied die-cut filter disks for ventilators, directly supporting efforts to address the current pandemic.

“Our extensive experience in the aerospace industry means we apply attention to detail and quality processes in all areas of our work. When slitting to narrow widths with quick turn-around times for the nonwovens industry, this is especially important,” Chris Lever, MD, said. “Over the past couple of years, we have invested heavily in highly specialised machinery which enables us to offer a wide range of cutting solutions with very short lead-times," Lever added.

The company is implementing a critical six-month R and D project to further develop and upscale its operations with support through the Sustainable Innovation Fund from Innovate UK.

Fibre2Fashion News Desk (SV)