The three-day fair for composites, technologies and applications will be held in Stuttgart, Germany.

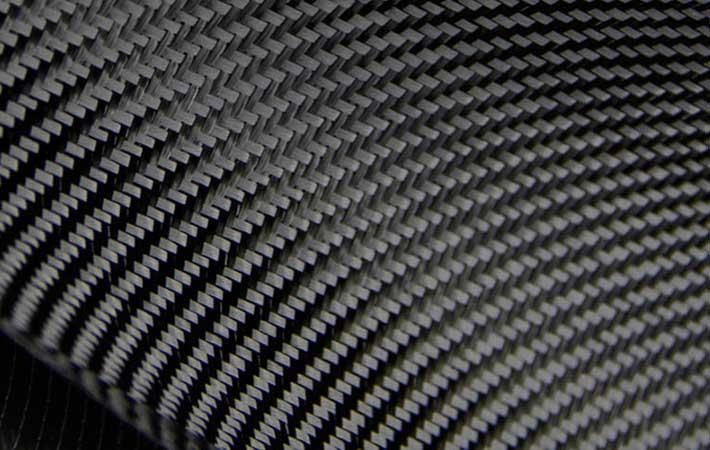

"FX is an adhesive applied to our fabrics, multiaxials and core materials. It is a new service that we provide for our customers who are looking for enhanced productivity and a healthier work environment," said Raphael Pleynet, head of composites and construction business at Chomarat.

The FX is an adhesive solution that makes it easier to position reinforcements in moulds. Available on most of Chomarat’s glass reinforcements, it is an alternative to adhesive sprays. It offers highly uniform placement, minimising the risk of delamination. "The resin cure is not affected by the addition of the adhesive and the mechanical performance is optimal. FX also facilitates the layup of parts, saving time and reducing the production costs," explained Philippe Sanial, head of R&T at Chomarat.

FX can facilitate the closed-mould production of large or complex-geometry parts, so the solution is suitable for a number of markets, including marine and transportation. FX emits no volatile organic compounds, so it contributes to better working conditions in user facilities.

The FX solution is available on Chomarat’s range of fabrics, multiaxials and core materials G-Weave, G-Ply, Rovicore, Roviflow and Rovimat. The adhesive can be placed on a single side, or both.

"By designing and producing an industrial solution that meets our customers' need to stay competitive, Chomarat remains true to the Group’s innovation values. And we are already studying how to integrate this function into new reinforcements," said Pleynet. (RR)

Fibre2Fashion News Desk – India