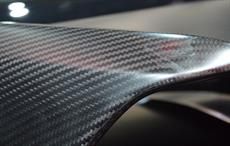

Composite Builders has become a supplier for Firefly Aerospace, an in-space mobility vehicle company. Firefly facilitates frequent launches at the lowest cost/kilogram. It is developing launch vehicles and in-space services that are affordable, convenient, and reliable. Composite Builders will supply carbon fibre components for these space vehicles.

Firefly, headquartered in Austin, affirms it is; “developing a family of launch vehicles and in-space services that provide industry-leading affordability, convenience, and reliability. Firefly’s launch vehicles utilise common technologies, manufacturing infrastructure and launch capabilities, providing Leo launch solutions for up to four metric tons of payload. Combined with Firefly’s in-space services, Firefly provides the space industry with access to frequent launches at the lowest cost/kilogram, enabling ambitious commercial and exploration missions from Leo to the Moon.”Composite Builders has become a supplier for Firefly Aerospace, an in-space mobility vehicle company. Firefly facilitates frequent launches at the lowest cost/kilogram. It is developing launch vehicles and in-space services that are affordable, convenient, and reliable. Composite Builders will supply carbon fibre components for these space vehicles.#

The fabrication of advance composite parts for aerospace vehicle requires a high-level of quality management. Shortly after inspections and testing of Composite Builders’ carbon fibre parts, Firefly gave Composite Builders the green light as an approved advanced composites manufacturer.

One of Firefly’s requirements is a high standard of quality control. Composite Builders is registered under ISO 9001;2015 and uses AS 9100 documentation in its processes. Every component Composite Builders makes has a thorough set of work instructions and quality documentations. Documents are recorded electronically and secured long term in private database.

Composite Builder has knowledge of risk management for advance composites fabrication. Although Firefly’s composite engineers provided the laminate schedule for their parts, Composite Builders understand every decision made for the lamination process and how carbon fibre will perform per skin. The external factors that can affect pre-impregnated carbon fibre are also controlled, such as material processing, exposure, contaminates, and temperature. There are several additional risk management processes which Composite Builders implement in composite fabrication to ensure quality and reliability to its customers.

“We maintain a high standard of operations; delivering a framework for consistent performance, reliable service and long-term continuous improvements. We work closely with our customers and are adaptable to meet their growing needs. Through this business relationship of success, Composite Builders looks forward to Firefly’s triumphs as they continue to advance the in-space travel,” Composite Builders says.

Fibre2Fashion News Desk (SV)