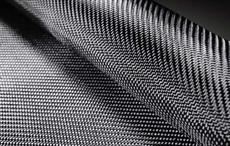

"At the JEC we will present the full range of our machine and system solutions for the composites industry," said Dr Josef Klingele, head of composite systems. "Manufacturing technologies are in a permanent state of evolution and optimisation. These days, both dry and fully impregnated tapes can be produced in widths up to 600 millimeters on the Dornier tape production line at manufacturing speeds as high as 30 meters per minute. Then, the finished tapes are processed further on the tape weaving machine to create textiles which are ideal for structural reinforcement and design applications."

In order to meet specific customer requirements, Dornier has established its own technology centre where it develops and tests complex machine and system concepts for optimal production of semi-finished products jointly with the customer. Trials are conducted in a tape laboratory facility here on the manufacture of thermoplastically fully impregnated tapes, and of tape-based fabrics on a tape weaving machine. A 3D weaving machine for complex multilayer fabrics and a high-performance weaving machine for flat weaves are also available for running tests. “It is just not possible to make the high-quality textile reinforcements needed for cars, aircraft and machine building on standard machines," said Klingele. (RR)

Fibre2Fashion News Desk – India