Injection bonding used to bond carbon-fibre parts to metal in side-frame applications along the roof. The carbon-fibre part is used as an inlay in a metal housing running along the A-pillar into the roof and down the D-pillar. This ensures stability of the passenger compartment in the case of a side-pole impact or rollover, as well as increasing vehicle torsional stiffness.

BETAFORCE composite bonding adhesives address specific customer requirements for production, such as open times and cycle times, without affecting mechanical properties. Dow Automotive Systems helps customers improve their assembly process efficiencies and enables wider application of carbon-fibre parts in manufacturing lightweight strategies.

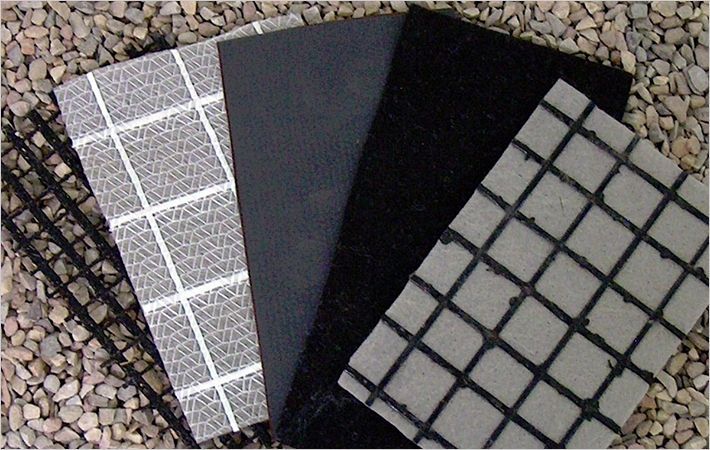

BETAFORCE is characterised by a high elongation factor which enables high energy absorption and flexibility with outstanding modulus providing the needed stiffness. Materials joined by BETAFORCE include carbon fibre with coated steel and with coated aluminum. Application areas includes roofing, complete carbon fibrer compartments or hang-on parts, such as doors. (NA)

Fibre2fashion News Desk - India