Dutch company IME Medical Electrospinning has developed revolutionary MediSpin XL platform for large-scale industrial production of reproducible and scalable fibre-based scaffolds for Class I, II and III medical devices. The platform ensures control of the crucial parameters of the electrospinning process, leading to identical and consistent end-products.

This marks a breakthrough in controlled large-scale production of well-defined scaffolds for implants and membranes using fibres ranging from nanometer up to micrometer scale. Dutch MedTech company IME Medical Electrospinning is the leader and scientific partner in electrospinning equipment development and services for medical devices and regenerative medicine.Dutch company IME Medical Electrospinning has developed revolutionary MediSpin XL platform for large-scale industrial production of reproducible and scalable fibre-based scaffolds for Class I, II and III medical devices. The platform ensures control of the crucial parameters of the electrospinning process, leading to identical and consistent end-products.#

Applying specific polymers, IME’s advanced equipment creates fibre-based medical device solutions that mimic the natural human extracellular matrix in nanometer and micrometer format for implants and membranes in the human body. Human cells recognise this artificial matrix (scaffold) as body’s own facilitating the repair of the damaged tissue for heart valves, blood vessels, nerves, tendons, skin and bone.

This is in contrast to implants and membranes of traditional structures, which are seen as foreign and therefore can lead to scar tissue or rejection phenomena. The MediSpin XL platform has been developed specifically for MedTech industrial manufacturing of medical devices and ensures firm control of crucial parameters of the electrospinning process.

Judith Heikoop, managing director of IME Medical Electrospinning, says: “The global launch of our state of the art production platform is testimony to our strong belief in the strategic goal of becoming the leading developer and producer of the most advanced electrospinning equipment for both large-scale production and research and development purpose, and broadens our trusted partnership worldwide in co-developing electrospun medical devices, which are seen as true game changers in the MedTech industry.”

Ramon Solberg, founder and managing director of IME Medical Electrospinning, says: “This technology enables the large-scale manufacturing of reproducible and scalable fibre-based scaffolds, the wonderful pieces of art that will substantially transform the medical device market for a wide variety of medical applications and thus revolutionise regenerative medicine.”

The electrospinning process is governed by a number of variables that are crucial for success in research and development, and also for large-scale manufacturing of fibre-based medical device solutions. Crucial parameters in fibre diameter and structure, porosity, mesh thickness and tensile strength are vital for the in-vitro and in-vivo functionality of products, but were challenging to control in the past. In particular, changes in temperature and relative humidity between the seasons and during the day, could lead to inconsistencies within one batch as well as between batches.

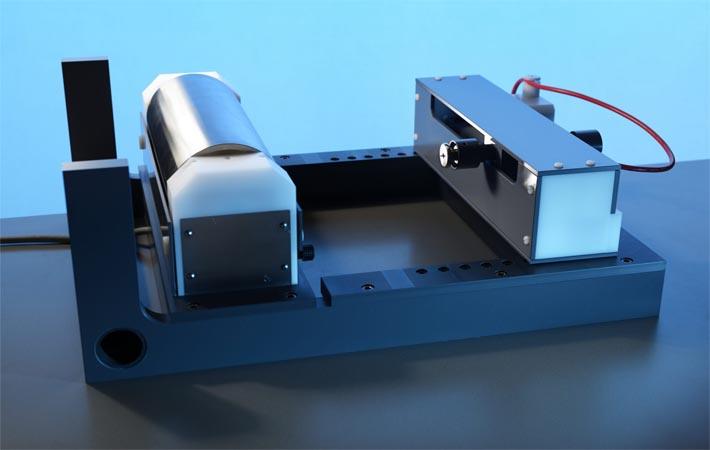

The MediSpin XL platform has resolved all this. MediSpin XL is the first large-scale production platform that eliminates all the important factors that might distort the electrospinning process, enabling an optimal process set-up and stability, including climate control and on-line quality monitoring measurements, ensuring a consistent end-product.

The MediSpin XL equipment is built using state-of-the-art materials and process controls in compliance with tight regulatory requirements for medical products to minimise the chance of product contamination during the process. Down-stream process steps such as cutting and blistering can be easily be included in the system. Ultimate automation minimises the need for operator intervention, which further adds to a reproducible process and minimisation of product contamination during the process. (SV)

Fibre2Fashion News Desk – India