Germany’s leading manufacturer of innovative technical textiles, Freudenberg Performance Materials, and Japan Vilene Company, Business Groups of Freudenberg Group, will be presenting solutions for the energy, medical, and automotive markets at the Asia Nonwoven Exhibition (ANEX), which will be held from June 6 to 8, 2018 in Tokyo, Japan, in stand 406.

The broad product spectrum ranges from battery separators and laminates comprising hydrophilic PU foams and hydroactive nonwovens to acoustic pads for vehicles.Germany's leading manufacturer of innovative technical textiles, Freudenberg Performance Materials, and Japan Vilene Company, Business Groups of Freudenberg Group, will be presenting solutions for the energy, medical, and automotive markets at the Asia Nonwoven Exhibition (ANEX), which will be held from June 6 to 8, 2018 in Tokyo, Japan, in stand 406.#

Freudenberg’s nonwoven electrodes with a unique three-dimensional fibre structure were specially developed to improve liquid circulation in redox flow batteries. These innovative electrodes feature a flexible design that enables them to be adapted to specific customer requirements.

Freudenberg’s safety separator for lithium-ion batteries consists of an ultra-thin PET nonwoven impregnated with ceramic particles. It remains stable at high temperatures and does not shrink.

Increased vehicle range is another key to the success of e-mobility. The Japan Vilene Company’s Ni-MH HV battery separators have been designed to meet this functional requirement. They are characterised by high-temperature resistance, excellent safety performance and a rapid rate of charge/discharge.

Following the introduction of an MDI-based foam, Freudenberg Performance Materials has continued with the systematic expansion of its portfolio in this field. The company has now entered series production of ISO 13485-compliant laminates comprising hydrophilic PU foams and hydroactive nonwovens. The combination of these two components, foam and nonwoven, can achieve a significant improvement in the ability of wound dressings to absorb and retain exudate.

Scaffolene, Freudenberg’s nonwoven fabric made from bio-resorbable polymers is extremely versatile in both characteristics and applications. Flexible and tear-resistant when dry, it remains stable even when wet, maintaining its structure and avoiding clumping. In addition to its use in wound healing, scaffolene technology opens up new therapeutic possibilities within other medical fields, including bio-surgery and regenerative medicine.

Japan Vilene Company’s transdermal backing materials are both elastic and offer beneficial physical properties. By reason of the superior elasticity in both directions, they provide comfort to the wearer and a soft-touch feeling.

The company’s disposable respirators provide protection against particulate matter. They are national-assay-approved, offer high particle removal efficiency and ensure easy breathing in polluted environments.

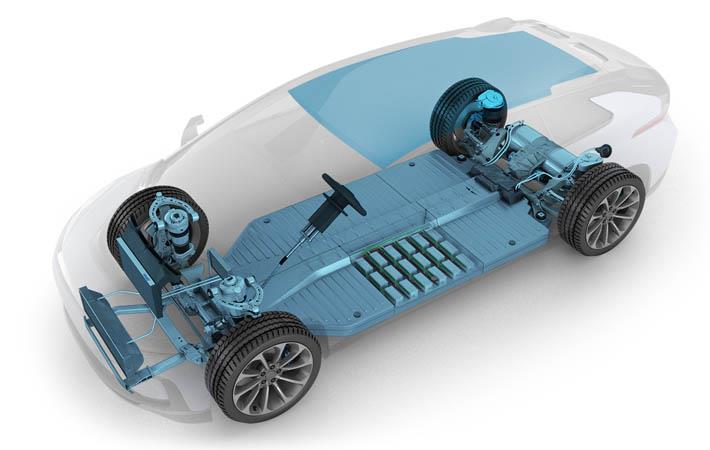

Freudenberg will be presenting innovative acoustic pads that provide outstanding sound absorption inside the vehicle. The light-weight pads help customers to save weight substantially and they are highly cost efficient. The pads are suitable for a wide variety of applications in the car such as door panels, headliners, trunk areas, wheel-houses, and so on. (GK)

Fibre2Fashion News Desk – India