GE Aviation has successfully tested the world’s first non-static set of light-weight, ceramic matrix composite (CMC) parts, by running rotating low-pressure turbine blades in a F414 turbofan demonstrator engine.

The demonstrator engine is designed to further validate the heat-resistant material for high-stress operation in GE’s next-generation Adaptive Engine Technology Demonstrator (AETD) program, currently in development with the United States Air Force Research Lab (AFRL).GE Aviation has successfully tested the world's first non-static set of light-weight, ceramic matrix composite (CMC) parts, by running rotating#

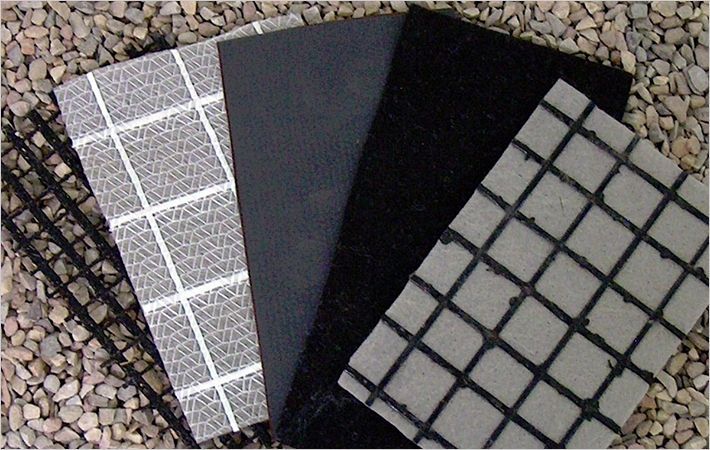

The introduction of rotating CMC components into the hottest and hardest-working sections of jet engines represents a significant technology breakthrough for GE and the jet propulsion industry.

The F414 CMC test, which endured 500 gruelling cycles, validated the unprecedented temperature and durability capabilities of turbine blades made from lightweight, heat-resistant CMCs, allowing for expansive deployment of the advanced manufacturing material in GE’s adaptive cycle combat engine and next-gen commercial engines, GE said in a press release.

As the rotating turbine blades made from CMCs are one-third the weight of conventional nickel alloys used in the high-stress turbine, they allow GE to reduce the size and weight of the metal disks to which the CMCs system is connected.

GE’s adaptive cycle engine will be much more durable than conventional engines because the CMC’s material temperature capability is hundreds of degrees higher than legacy nickel-based alloys currently in service in both commercial and military engines.

Jonathan Blank, general manager of CMC and advanced polymer matrix composite research at GE Aviation said, “Going from nickel alloys to rotating ceramics inside the engine is the really big jump. But this is pure mechanics. The lighter blades generate smaller centrifugal force, which means that you can slim down the disk, bearings and other parts. CMCs allow for a revolutionary change in jet engine design.”

GE Aviation is a world-leading provider of jet engines, components, and integrated systems for commercial and military aircraft. (GK)

Fibre2fashion News Desk - India