Institut fur Textiltechnik of RWTH Achen University (ITA) has bagged the third AVK prize in the Research & Science category at Composite Europe, in Stuttgart, Germany. The awards aim to promote the development of new products and applications using fibre reinforced plastics as well as new procedures and processes for manufacturing these FRP products.

In fibre reinforced plastic (FRP) production, stamp forming is one of the most economical processes for automated large-scale production, for example in the BMW i-series. However, the current processes are susceptible to draping errors and a high proportion of waste. The innovative process by ITA can now significantly reduce the scrap rate and reduce the waste rate of high-priced reinforcing textiles, such as carbon fibre textiles, by up to 50 per cent. Sven Schöfer from ITA achieved this effect with his work ‘Development of a textile-based material feed to increase the preform quality during stamp forming of reinforcing layers’, according to a press release by the University.Institut fur Textiltechnik of RWTH Achen University (ITA) has bagged the third AVK prize in the Research & Science category at Composite Europe, in Stuttgart, Germany. The awards aim to promote the development of new products and applications using fibre reinforced plastics as well as new procedures and processes for manufacturing these FRP products.#

In stamp forming, clamping grippers are usually used in industry to feed the stacked individual layers to the forming process and position them on the lower tool via a clamping frame or hold-down device. Due to the clamping grippers, the cutting proportion of cost-intensive reinforcing textiles is high, as additional material at the textile edge is necessary with clamping systems. Other approaches to feeding the reinforcing semi-finished product during forming and simultaneously improving the draping quality are also not economical: they are usually only designed for certain textile cuts, cannot be automated, are prone to errors or are expensive special solutions.

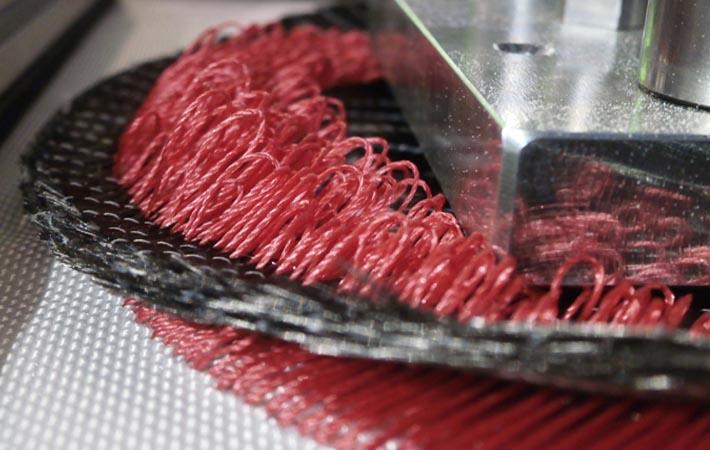

There is currently no system in the industry that can apply retention forces along a final contour with low waste and remains flexible in terms of geometry. The innovative process developed works with a detachable textile joint, a so-called tufting seam. It allows the single layers to slide off during the forming process under a retention force dependent on the seam design.

This reduces or completely eliminates draping errors in previously critical areas, even with complex preform geometries. This leads to a significant increase in preform quality and a reduction in scrap rates. The process is also highly efficient, as tensile forces can be applied to any component geometry on near-net-shape blanks. This reduces the material input by up to 50 per cent. (GK)

Fibre2Fashion News Desk – India