PRO-SOFT now lets users load and run calibration files via QR code. As soon as a work-piece is placed in the detection range of the DTEC-PRO camera system, the camera scans the QR code linked to files such as the associated order documentation. Upon the user’s confirmation, the calibration file assigned to the tool is then opened and the calibration automatically started.

Another new feature is the unit calibration, which sees laser projectors and camera systems treated as a single unit in PRO-SOFT. It is also possible to combine one or more DTEC-PRO camera systems with one or more CAD-PRO laser projectors.

PRO-SOFT’s camera live image displays the detection range to the user from the perspective of the camera. This allows the user to optimally position the tool in the production range and ensure the target is visible to the camera before production begins, resulting in increased production quality.

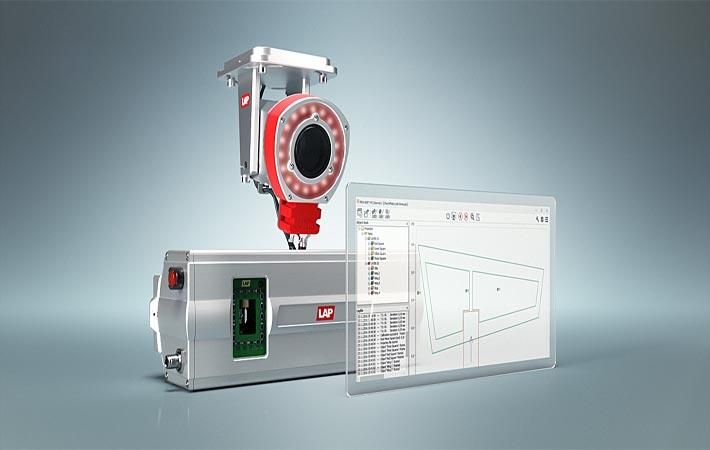

In combination with CAD-PRO laser projection systems and the PRO-SOFT operating software, the DTEC-PRO camera system increases efficiency in flexible composite manufacturing processes, especially when many different tools are used. The DTEC-PRO camera system accelerates set-up processes thanks to quick and automatic calibration; CAD-PRO laser projectors ensure efficiency and precision during the lay-up process; and the PRO-SOFT operating software optimises workflows, starting from the preparation phase all the way to quality assurance, thus minimising throughput time. (GK)

Fibre2Fashion News Desk – India