7th Feb 2019

Netzsch Analyzing & Testing and University of Southern Queensland (USQ) have partnered to focus on advancing the automated production of composite materials using dielectric sensor technology. The sensor helps in characterisation of critical material properties during making of carbon fibre-reinforced plastics reducing cycle times and manufacturing...

7th Feb 2019

Arville has taken delivery of three new high-spec weaving looms, the first part of a suite of new machinery worth over £1.2m. The rapier-style looms have been shipped from Europe and will contribute to a significant expansion of production capacity at Arville’s Wetherby site. Three more such machines will be added to its factory later this year.

6th Feb 2019

The Sanitized Odoractive 10 odour management technology has now been granted the bluesign sustainability label, the skin-friendly certification from the Hohenstein Institute, and the Eco Passport by Oeko-Tex label. Sanitized is the leading producer of antimicrobial hygiene function and material protection for textiles and plastics from Switzerland.

5th Feb 2019

The Momentum Group is collaborating with Composites UK to support research and development tax credit claims within the industry. Within the composite sector, research and development activities are abundant. R and D tax credits are valuable form of tax relief in the UK, allowing companies the opportunity to further invest and advance product...

5th Feb 2019

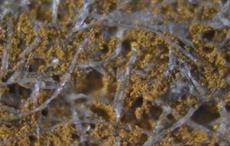

EconCore and Covestro have joined hands to combine their technologies for the purpose of producing strong and lightweight honeycomb panels with outstanding performance. One of the targeted key performance aspects is to comply with fire, smoke, toxicity (FST) requirements for public transportation applications, including railway and aerospace.

5th Feb 2019

A multidisciplinary team of scientists from Imperial College London has developed technology to print metals such as silver, gold and platinum onto natural fabrics and shown that it could be used to incorporate batteries, wireless technologies and sensors into fabrics like paper and cotton textiles. This may be used in clothing for monitoring health.

4th Feb 2019

Military uniform manufacturer Propper International is unveiling many of its camouflage items in authentic US Army Operational Camouflage Pattern (OCP). Licensed mills are producing the pattern for the first commercially available applications. Many of the Propper camouflage garments will soon be available in OCP as well, including ACUs and select...

4th Feb 2019

Two scientists from the University of Massachusetts Amherst have created a fabric that can harvest body heat to power small wearable microelectronics such as activity trackers. Though wearable biosensors and data transmitters for personalised health monitoring have been developed, they require a lot of energy, while power sources can be bulky and heavy.

4th Feb 2019

Virgin Galactic and Under Armour are collaborating to create a new generation of space apparel and footwear, as well as an astronaut performance training programme. Over the 50-plus years since space travel began, only 568 people have ever been to space. The game is changing as visionaries come together to make space accessible to the Earth-bound...