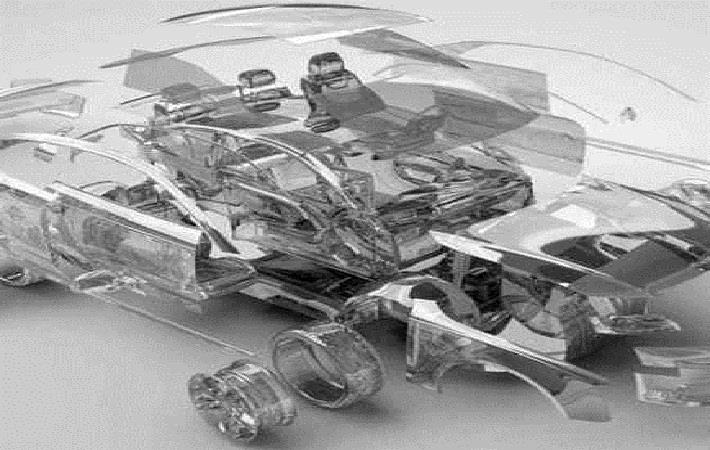

The fibre sizing solutions help industries including automotive, transportation, construction, aerospace, energy, and sports, according to a press release by Michelman.

Visitors to Michelman’s booth #113 will find a focus on Hydrosize Carbon, which allows carbon fibre manufacturers to optimise the interfacial adhesion between polymers and fibres by tailoring the surface chemistry of their reinforcement fibres to the chemistry of the matrix resin. Various grades are available and offer a wide variety of solutions depending on resin compatibility, fibre type, and desired composite performance.

Designed for polyamides including high-temperature applications, the Hydrosize Carbon 200 Series is APE, solvent, and VOC-free and is perfect for fibre reinforced nylon composites where greater thermal stability is required. Coolant pumps are a typical automotive application. Other benefits of these small particle size dispersions include excellent film-forming properties and high strand integrity.

Formulated for polycarbonates (PC) and other PC blends such as PC-ABS, the Hydrosize Carbon 300 Series produces good chemical resistance along with interfacial adhesion to polymer systems. Appropriate applications include laptop cases or other electronic components.

The Hydrosize Carbon 400 Series includes high-performance grades that can withstand the extreme processing temperatures that many high-temperature thermoplastics require. Appropriate materials include PEEK, PPS, PEI, and others used to produce various composite engine components. This series exhibits excellent thermal stability, mechanical properties, and low creep. It is especially suited for chopped carbon fiber applications.

The Hydrosize Carbon 700 Series is formulated to improve the performance of carbon fibre reinforced vinyl ester composites and is perfect for under-the-hood applications. Its proprietary chemistry allows for increased adhesion between the carbon fiber and various vinyl ester compounds. (PC)

Fibre2Fashion News Desk – India