At this year's Anex from 13 - 15 June in Seoul, Korea, Oerlikon Neumag exhibits its nonwoven technology portfolio with a special focus on enhanced product performance with an innovated spunbond technology at booth L24 in hall 10. In addition to the supply of standalone equipment for spunbond, meltblown and airlaid production, Oerlikon Neumag focuses on establishing partnerships for turnkey production lines.

Oerlikon Neumag presents its innovated spunbond technology allowing nonwoven makers to produce materials with properties that exceed the commercial standards of today and being especially suitable for durable applications. The company will demonstrate the enhanced product performance which is accomplished by modification of the former technology.At this year's Anex from 13 - 15 June in Seoul, Korea, Oerlikon Neumag exhibits its nonwoven technology portfolio with a special focus on enhanced product performance with an innovated spunbond #

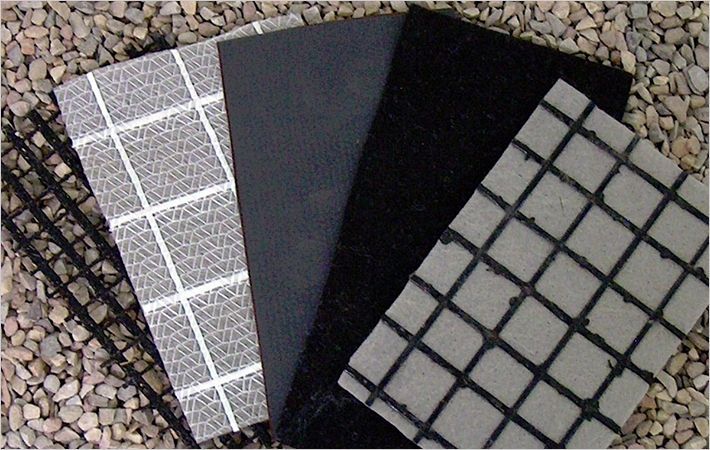

The focus of Oerlikon Neumag was to reengineer the equipment to process PP and PET which is thermo bonded or needled at full throughput of 240 kg/h/m (PP) and 300 kg/h/m (PET). However, the processing of distinctively different polymers such as PP, PE, PET and PLA or the use of bicomponent technology to combine them is still offered, all from a single platform. With the new process, a tensile strength MD/CD ratio around 1 can be achieved.

The durable nonwoven sector is known as a market with high growth rates outpacing that of disposables and a segment with opportunities for innovators in roll goods production. Oerlikon Neumag and their spunbond portfolio enables producers of durable nonwovens like geotextile, roofing or carpet backing to reduce energy costs, expand capacities and secure After Sales services.

Oerlikon Neumag offers market leading meltblown equipment with which companies can produce material especially suitable where fluid and air management are decisive, as filtration and medical media. Like Oerlikon Neumag's spunbond technology, the meltblown equipment has undergone a redesigning. The newly engineered system connects the spinning lines to a rotating element consisting of the quenching system, vacuum box and die assembly. The synchronised rotation of all three elements enables the adjustment of the sheet width to individual requirements and considerably reduces the waste production. Further Oerlikon Neumag presents its new dual drum forming technology which allows production of high loft webs with high filtration characteristics with a minimalized pressure drop.

The meltblown line is able to process PP, PET, PBT, PA, PC, TPU and PPS, producing up to 150 kg/h/m with a basis weight ranging from <1 gsm to >300 gsm. Meltblown can be produced as a standalone medium or combined with spunbond material in an inline process creating for example SMS nonwovens with diverse properties.

Oerlikon Neumag will be showing its latest developments in airlaid technology at the Anex. With the modified air flow in the forming zone, which is the heart of the airlaid technology, producers of airlaid products, like absorbent core materials for hygiene applications, are able to increase production speed by up to 40% and sustain a high quality level. The airlaid equipment allows the production of wide width webs either out of 100% pulp fibers or mixtures of different fibers and powders with a high efficiency and uniformity.

The well-equipped spunbond and meltblown R&D center is a perfect place to start a partnership with Oerlikon Neumag for individual trials. The cooperation can evolve in a long term partnership from equipment supply to After Sales support throughout the lifecycle with skilled service offerings and a worldwide available Oerlikon Textile service pool.

Oerlikon Neumag