At the upcoming IDEA show, Oerlikon Neumag will present its extensive technology portfolio for production of nonwovens like spunbond, meltblown, airlaid and for production of carded nonwovens.

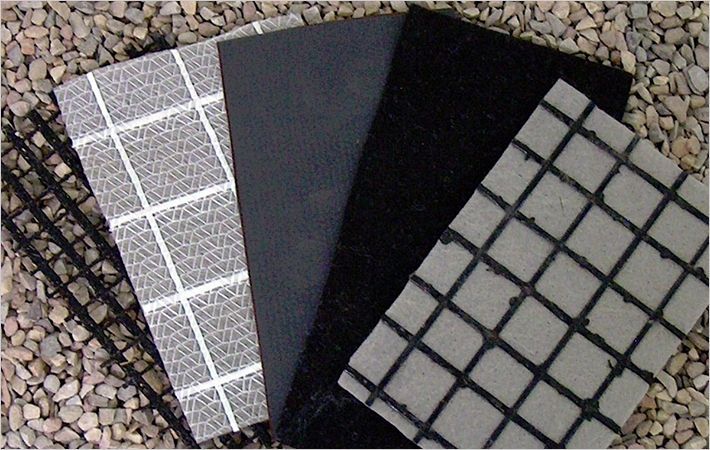

According to an Oerlikon press release, areas of application include technical, such as filtration, roofing, geotextiles and automotive, in addition to medical and hygiene applications.At the upcoming IDEA show, Oerlikon Neumag will present its extensive technology portfolio for production of nonwovens like spunbond, meltblown#

“The proportion of nonwovens manufactured directly from polymer granulates now amount to almost 50 per cent of the total market, and its share is continuing to grow,” the company said.

“The trend is towards lighter surface weights that despite everything still meet the high quality standards,” the German producer of nonwovens technology observed.

“Benchmark comparisons with current products in Europe show that with its spunbond technology, required qualities are achieved with reduced surface weights resulting in 5 per cent raw material savings,” it added.

The company has also optimised the energy consumption of its systems and so, the new generation of systems saves almost 20 per cent of the energy requirement in spinning alone.

Together with the raw material savings and further technology optimisations, the conversion costs are up to 30 per cent below those of the spunbond systems producing today.

As per the company, the Oerlikon Neumag meltblown process today enables cost-efficient manufacture of meltblown nonwovens with the quality standards of tomorrow.

In light airlaid nonwovens its technology with a high uniformity and homogenous fibre placement, even with extremely thin nonwovens, is setting standards.

For manufacturers of carded nonwovens, who in future would like to produce their fibres in-house, Oerlikon Neumag offers a comprehensive technology portfolio.

The economically viable system capacities for special mono and bio fibres made of PP, PET and other polymers start at 5 tons per day. (AR)

Fibre2Fashion News Desk – India