Polyonics has introduced a brand new line of engineered tapes designed for use in and around batteries. The ultra thin, flame retardant Polyonics battery tapes help consumer and industrial battery designers and engineers meet their top priorities of safety, performance, size and weight. The highly engineered tapes provide protection and bonding while isolating batteries.

The halogen free, REACH and RoHS flame retardant tapes are available with 13, 25 and 50µm amber or black polyimide films. A variety of adhesives (PSAs) are also available providing total thicknesses as low as 41µm. A variety of liners are offered to suit most die cut and auto application processes. The new line of battery tapes includes optional ESD/antistatic and anti-counterfeit features. Polyonics has introduced a brand new line of engineered tapes designed for use in and around batteries. The ultra thin, flame retardant Polyonics battery tapes help consumer and industrial battery #

Today's state of the art Li-Ion and Ni-Cd batteries provide high energy and capacity, but at the risk of low thermal run-away temperatures (<150C). Once in motion, a thermal runaway can produce flammable gases that can lead to fire and/or explosion as has been witnessed in the smart phone market. Thermal management is the key to helping reduce the chances of thermal runaway and optimal battery performance.

Heat resistant Polyonics battery tapes offer a proven, economical method to isolate batteries from external heat generated by adjacent components and/or additional batteries. The tapes are designed to survive prolonged high temperature exposure seen during electronic device operation as well as temperature cycling. They also provide permanent closures to battery cases while reducing the risk of fire. If a fire does occur, the halogen free, REACH and RoHS compliant tapes are flame retardant so they will not add fuel to the fire and thus not propagate it.

Polyonics battery tapes help manage thermal issues in batteries in part because they remain dimensional stable at high temperatures (see chart second from top right). When a tape changes shape at elevated temperatures it can expose the battery to extreme heat thus risking reduced performance. Polyonics high temperature polyimide battery tapes offer a high degree of dimensional stability and maintain their original shape at temperatures up to 300°C. The ultra-thin tapes are available in amber or black polyimide and total construction thicknesses starting at 41µm.

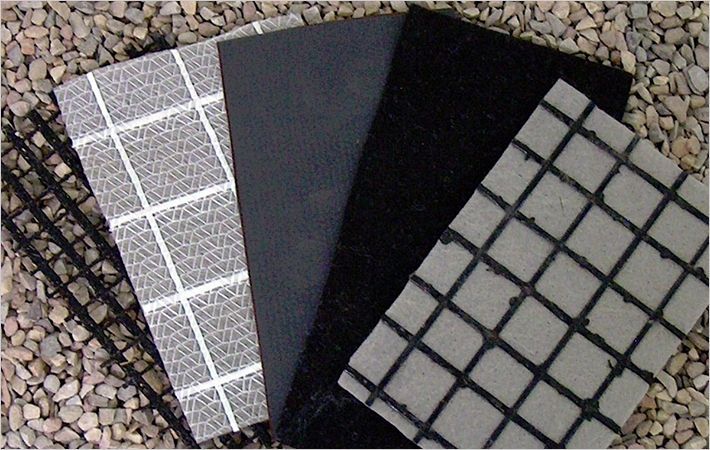

The polyimide films incorporated in Polyonics tape constructions provide high strengths, low coefficients of thermal expansion and resistances to chemicals. But the film is only half of the equation. The design of the flame retardant adhesives (PSAs), in many regards, is even more important to the overall success of the tape especially when wrapped over tight radii as is the case for consumer smart phone and tablet batteries.

Polyonics formulates it high temperature PSAs using ThermoGard technologies that enhance the tapes ability to remain dimensionally stable over a wider range of temperatures. The acrylic fire retardant PSAs are available in a variety of thicknesses and strengths to best match the application and substrate. The tapes combine these unique PSAs with polyimide films to provide ideal adhesion for insulating and isolating batteries from high temperatures.

Polyimide double coated battery tapes provide non-mechanical means of attaching batteries to frames, chassis, etc. where preventing the propagation of fire is also required. The tapes provide strong, thin conformal bond lines and can be configured with a variety of PSAs deferentially coated on the top and bottom surfaces to optimize the bond adhesion to dissimilar surfaces.

The battery bonding tapes include liners that allow die cutting and auto application and can be selected to optimize each die cut process. This feature increases the precision of the bond, reduces waste and improves manufacturing and assembly inefficiencies.

Polyonics polyimide battery tapes incorporate FlameGard technologies that include a variety of chemical mechanisms that help seal batteries to help prevent the escape of gasses. With exposure to high temperatures the tapes produce a char layer that helps prevent the propagation of flames. The PSA's are also antistatic to help ease tape die-cutting and installation while protecting batteries from possible ESD damage. The tapes are available in several thicknesses including <50 microns to fit even the most compact smart phone or tablet designs.

The tapes are tested for compliance to some of the most stringent industry flammability standards including UL94 VTM0, FAR 25.853 and BSS 7238.7239.

Polyonics