Recycled carbon fibres have found use in rail vehicles. In a new project in the UK, a consortium of companies is working on multi-material designs using recycled carbon fibres with an aim to reduce costs and track wear and improve performance. The two-year project is expected to get completed in the end of 2018 with a grant of £1.25 million.

Recycled carbon fibres have found use in rail vehicles. In a new project in the UK, a consortium of companies is working on multi-material designs using recycled carbon fibres with an aim to reduce costs and track wear and improve performance. The two-year project is expected to get completed in the end of 2018 with a grant of £1.25 million.#

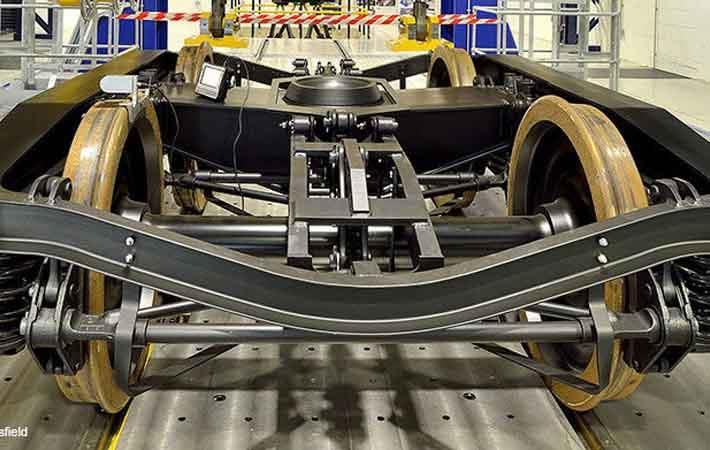

The project funded by the UK's RSSB involves a consortium of companies comprising CCT, the University of Birmingham, the University of Huddersfield, with additional support from Alstom. The aim is to reduce weight and optimise vertical and transverse stiffness in order to decrease vehicle operating costs, infrastructure damage and environmental impact.

Recycled carbon fibres have found use in rail vehicles. In a new project in the UK, a consortium of companies is working on multi-material designs using recycled carbon fibres with an aim to reduce costs and track wear and improve performance. The two-year project is expected to get completed in the end of 2018 with a grant of £1.25 million.#

ELG Carbon Fibre has been assigned the task of managing the project and providing recycled carbon fibre materials. The company will deliver the multi-material design in which recycled carbon fibres are expected to feature prominently.

Recycled carbon fibres have found use in rail vehicles. In a new project in the UK, a consortium of companies is working on multi-material designs using recycled carbon fibres with an aim to reduce costs and track wear and improve performance. The two-year project is expected to get completed in the end of 2018 with a grant of £1.25 million.#

It is expected that there will be reduction of track wear due to reduction in vertical and transverse loads on the rails; hence infrastructure maintenance costs will drop. Other expected benefits include improved reliability and operational availability through the use of an embedded health monitoring system, and reduction in energy consumption and global warming footprint.

Recycled carbon fibres have found use in rail vehicles. In a new project in the UK, a consortium of companies is working on multi-material designs using recycled carbon fibres with an aim to reduce costs and track wear and improve performance. The two-year project is expected to get completed in the end of 2018 with a grant of £1.25 million.#

In the phase 1, the consortium will develop an optimised design and seek regulatory approval for primary composite structures in rail applications. Phase 2 of the project envisages manufacture and testing of full scale demonstrators under representative service conditions using the dynamic test rig at the University of Huddersfield. The embedded health monitoring system being developed by the School of Metallurgy and Materials of the University of Birmingham will be demonstrated through these tests. (SV)

Fibre2Fashion News Desk – India