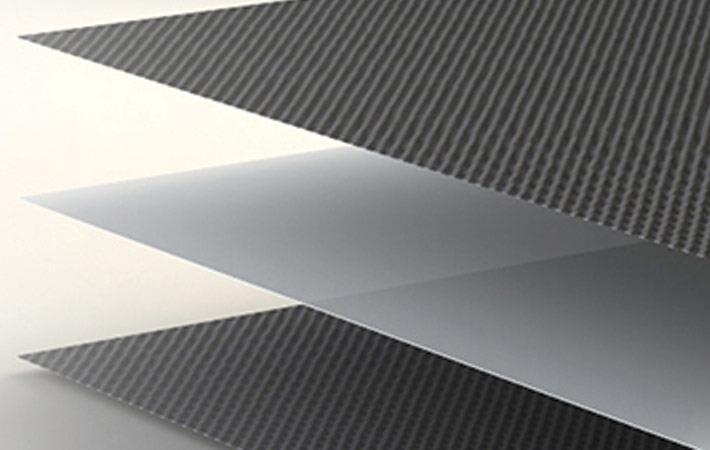

Significant advancements have been made by using nanofibre interleaving veils to increase the impact strength, delamination resistance and fatigue life of composites.

"We are also increasingly seeing evidence that nanofibre veils outperform thermoplastic toughening particles and microfibre veils, and nanofibre veils can also improve the mechanical properties of composites containing already toughened resin systems," said Dr Gareth Beckermann, nanofibre applications engineer, Revolution Fibres.

"In some situations, the addition of lightweight nanofibre interleaving veils can improve delamination resistance by up to 170 per cent, impact strength can be improved by up to 20 per cent, and fatigue life can be improved by nearly 400 per cent, all with negligible laminate weight and thickness gains. Nanofibre veils can also be used for localised reinforcement as opposed to having to apply veils to the whole composite part," he added.

"We expect 2017 to be a significant year for Xantu.Layr production as many clients are coming to the end of their R&D program cycles with positive results," said Brent Tucker, operations manager, Revolution Fibres.

"This increased production capacity is a huge benefit to all because it will lead to cost reductions, especially for customers wanting larger volumes," added Tucker.

Revolution Fibres' ground breaking electro-spinning technology creates nanofibre out of a range of synthetic and bio-derived polymers. Nanofibres are textiles made from super fine fibres between 100-500 nanometres in width, and are made from a wide variety of polymers. These small fibres can create vast changes in mechanical strength, reactivity and conductivity, among many other properties.

"The company’s aim now is to get more people to use Xantu.Layr, which is why it has introduced smaller quantity Hobby and Starter Packs to the range. It is an incredibly versatile material and our goal is to make it easier for designers, production engineers and hobbyists to purchase Xantu.Layr in smaller quantities and to give them greater access to the technology," said Iain Hosie, CEO, Revolution Fibres.

Revolution Fibres is interested in talking to distributors to spread the technology further, especially in Asia and the US.

"It is a product that will fit well with a number of distributors' product portfolios to provide a significant and unique offering for their clients. We are also keen to work with more carbon fibre pre-pregging companies to integrate Xantu.Layr directly into pre-preg materials as an additional toughening measure," added Hosie. (KD)

Fibre2Fashion News Desk – India