Roth Composite Machinery from Steffenberg, Germany, will display its machine manufacturer competences in filament winding, prepreg and organic sheet production at the international composites industry trade show - JEC World 2018 - in Paris, to be held during March 6-8, 2018. JEC World in Paris is the only trade show that unites the global composite industry.

The show is an indication of the industry’s commitment to an international platform where users can find a full spectrum of processes, new materials, and composite solutions.Roth Composite Machinery from Steffenberg, Germany, will display its machine manufacturer competences in filament winding, prepreg and organic sheet production at the international composites industry trade show - JEC World 2018 - in Paris, to be held during March 6-8, 2018. JEC World in Paris is the only trade show that unites the global composite industry.#

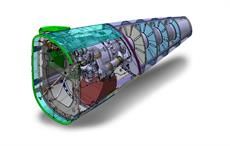

The special machine builder from Steffenberg has been developing, planning and manufacturing filament winding machines for more than 50 years and has almost 30 years of experience in the development of fully-automated machines in this sector. More than 500 production plants of the technological leader are already in use all over the world.

Advantages of the production lines are the short installation periods enabling that the production processes can start more quickly. The handling of all kinds of fibres - from simple glass fibres to sensitive, highly strong fibres – is also the know-how of the company.

Filament Winding plants of 120 tonnes component weight and three driving carriages are tested in series production. Roth Composite Machinery constructs production lines working with highest accuracy for the manufacture of hydrogen tanks. The company also has lab machines for filament winding and prepreg at their customers disposal for the design or process development.

Roth Composite Machinery has set new standards in the mechanical engineering as regards the series production of liquefied petroleum gas vessels using the filament winding technology. The company has developed a fully-automated production line containing four winding stations having five spindles each. The high degree of automation of the production line guarantees maximum productivity. (SV)

Fibre2Fashion News Desk – Indiat