Scientists at Saarland University have developed a new method to make electro-sensitive fabrics, called e-textiles, in a simple way. The method makes it possible to convert textiles and garments into e-textiles, without affecting their original properties. The textiles remain thin, stretchable and supple. The electrical properties are “dyed” into the fabric.

“Our goal was to integrate interactive functionalities directly into the fibres of textiles instead of just attaching electronic components to them,” says Saarbrücken-based computer science professor Jürgen Steimle. In his research group on human-computer interaction at Saarland Informatics Campus, he and his colleagues are investigating how computers and their operation can be integrated as seamlessly as possible into the physical world. This includes the use of electro-interactive materials.Scientists at Saarland University have developed a new method to make electro-sensitive fabrics, called e-textiles, in a simple way. The method makes it possible to convert textiles and garments into e-textiles, without affecting their original properties. The textiles remain thin, stretchable and supple. The electrical properties are “dyed” into the fabric.#

Previous approaches to the production of these textiles are complicated and influence the haptics of the material. The new method makes it possible to convert textiles and garments into e-textiles, without affecting their original properties – they remain thin, stretchable and supple. This creates new options for quick and versatile experimentation with new forms of e-textiles and their integration into IT devices.

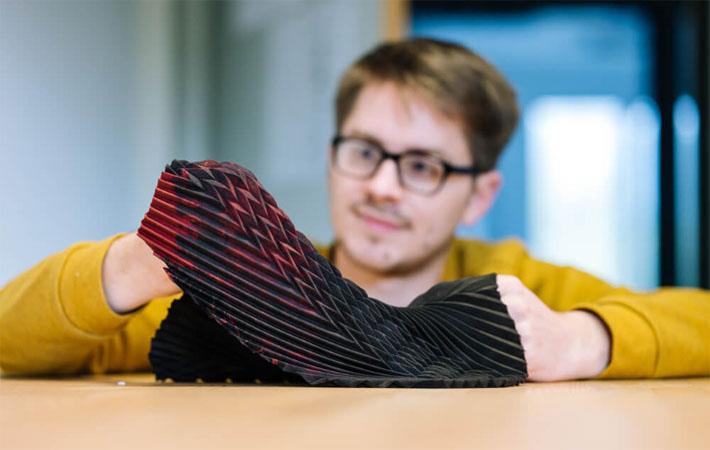

“Especially for devices worn on the body, it is important that they restrict movement as little as possible and at the same time can process high-resolution input signals,” explains Paul Strohmeier, one of the initiators of the project and a scientist in Steimle’s research group. To achieve this, the Saarbrücken researchers are using the in-situ polymerisation process. Here, the electrical properties are “dyed” into the fabric. A textile is subjected to a chemical reaction in a water bath, known as polymerisation, which makes it electrically conductive and sensitive to pressure and stretching, giving it so-called piezoresistive properties. By “dyeing” only certain areas of a textile or polymerising individual threads, the Saarbrücken-based computer scientists can produce customised e-textiles.

In their test runs, the researchers have produced gloves that can digitally capture hand movements, a zipper that transmits different electric currents depending on the degree of opening, and sports tapes that act as user interfaces that are attached to the body.

Also, materials other than textiles can be treated with the process. Audrey Briot, an artist from Paris, has created an evening gown with touch-sensitive feathers that generate sounds via a computer when touched. She polymerised the feathers using the Saarbrücken computer scientists’ method. The dress was nominated for the STARTS Prize of the European Commission.

The research was published in 2020 at the ‘ACM Conference on Computer Human Interaction (CHI)’.

Fibre2Fashion News Desk (SV)