SFS intec has joined hands with TxV Aero Composites to re-design an aircraft storage bin bracket. The aim is to achieve weight and cost savings within the quality and price-sensitive air transportation industry. Originally made from aluminum, the new bracket will be made of Victrex AE 250 composites overmolded with Victrex PEEK(polyetheretherketone) polymer.

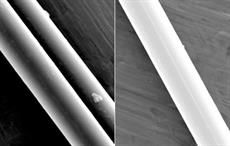

SFS is qualifying TxV’s hybrid overmolded composite part for use in a commercial aircraft. The weight, size, complex geometry and high load-bearing specifications of the overhead storage bin bracket made the SFS part a suitable candidate for the pioneering hybrid overmolding technique at TxV. Another consideration was the 60-70 per cent scrap produced through several milling steps required for the original aerospace grade aluminum bracket.SFS intec has joined hands with TxV Aero Composites to re-design an aircraft storage bin bracket. The aim is to achieve weight and cost savings within the quality and price-sensitive air transportation industry. Originally made from aluminum, the new bracket will be made of Victrex AE 250 composites overmolded with Victrex PEEK(polyetheretherketone) polymer.#

Sascha Costabel, head of Innovation at SFS Intec Aircraft Components said, "Our decision to work with TxV is a strategic one. We are convinced that thermoplastic composite components will play an increasingly larger role in the manufacture of aircraft. It may well be that several different technologies will each have a role in the future of aircraft production. TxV’s hybrid overmolding process, is a good option for components that must withstand high levels of mechanical stress and geometries that require multiple processing steps where conventional machining is used."

The processing and performance advantages of PAEK thermoplastic composites, combined with state-of-the-art automated manufacturing, position TxV to meet the industry’s cost and weight challenges. Finished composite parts, complete hybrid overmolded components and assemblies are produced using continuous manufacturing processes with cycle times measured in minutes rather than the hours required by thermoset alternatives. These innovative products can deliver weight savings of up to 60 per cent over conventional metallic solutions.

"This project represents an exciting commercial application of our overmolded hybrid part technology,” commented Jonathan Sourkes, senior account manager at TxV. “SFS intec recognises the benefits of our approach to part manufacturing in terms of processing efficiencies and overall system cost savings. Scrap reduction, decreased weight, elimination of secondary processing and lower part count are all benefits of moving from metal to a hybrid overmolded composite solution.”

Victrex AE 250 composites are based on the PAEK (polyaryletherketone) family of high performance polymers and are specifically designed for lower temperature processing. This enables a unique hybrid molding process that combines the strength of continuously-reinforced thermoplastic composites with the design flexibility and proven performance of Victrex PEEK (polyetheretherketone) overmolding polymers - in this case, Victrex PEEK 150CA30.

Commercial aircraft use thousands of brackets and system attachments from the cockpit to the tail of the plane. As a result, these components can account for significant cost and weight. The high performance PAEK polymer-based components can be manufactured more efficiently than conventional thermoset alternatives and can deliver significant weight savings compared to aluminum, stainless steel and titanium while offering equivalent or better mechanical properties such as strength, stiffness, and fatigue. In the aircraft industry, of course, weight savings translate into lower fuel costs and increased productivity. Victrex and Tri-Mack together create TxV.

TxV Aero Composites came into being in early 2017 as a joint venture between Victrex plc, a leading supplier of PAEK and PEEK-based high-performance polymer solutions, and Tri-Mack Plastics Manufacturing Corporation. The objective was to accelerate the commercial adoption of polyketone-based composite applications throughout the aerospace industry, by leveraging the manufacture of parts utilising new and innovative processes. The US-based manufacturing facility is operational and production ready. (SV)

Fibre2Fashion News Desk – India