Shima Seiki Mfg., Ltd, a leading computerised knitting machine manufacturer of Wakayama, Japan, together with its European subsidiary, Shima Seiki Europe, Ltd., is set to participate in the Meet the Manufacturer 2017, UK’s leading textile trade show and manufacturing exhibition, to be held in London, England, on May 24 and 25, 2017, in booth K-10.

Meet the Manufacturer is a trade show and sourcing event showcasing British manufacturing of clothing, textiles, fashion accessories, homewares and leathergoods, and features various manufacturers and suppliers to the UK apparel and textile industries. Shima Seiki will participate as textile machinery supplier while demonstrating its seam-free Wholegarment knitting technology.Shima Seiki Mfg., Ltd, a leading computerised knitting machine manufacturer of Wakayama, Japan, together with its European subsidiary, Shima Seiki Europe, Ltd., is set to participate in the Meet the Manufacturer 2017, UK's leading textile trade show and manufacturing exhibition, to be held in London, England, on May 24 and 25, 2017, in booth K-10.#

Recent consumer trends such as increase in online shopping activity have changed supply chain requirements, with growing demand for mass customisation and short turnaround. The combination of Shima Seiki’s pioneering Wholegarment knitting technology that allows a garment to be produced in its entirety without the need for linking or sewing, along with the SDS-ONE APEX3 3D design system offers an ideal manufacturing model to support such trends.

Demonstrating the latest in Wholegarment knitting technology will be the flagship MACH2XS machine that features the company’s original SlideNeedle on 4 needle beds and patented spring-loaded full-time sinker system. Capable of Wholegarment knitting in all-needles, MACH2XS offers great flexibility for knitting beautiful and sophisticated, high-quality Wholegarment products with a seemingly endless variety of knit patterns at very high efficiency. At Meet the Manufacturer, Shima Seiki will show traditionally woven items such as gilets and jackets using a special inlay technique that yields novel knit-weave hybrid fabrics that are suited for such items.

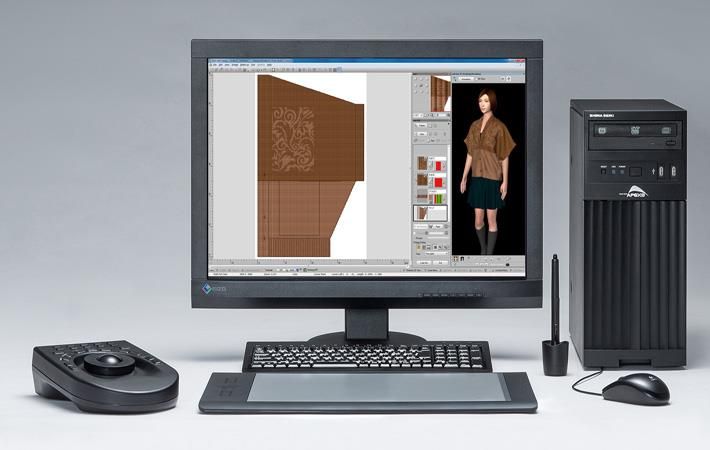

Also on display will be the SDS-ONE APEX3 3D design system, which provides comprehensive support throughout the apparel supply chain, integrating production into one smooth and efficient workflow from yarn development, product planning, and design to production and even sales promotion. Of particular interest is its ultra-realistic simulation capability that realises Virtual Sampling. When countless variations must be evaluated before arriving at a final design, virtual product samples can be used to streamline the decision-making process by minimising the enormous amount of time and cost normally associated with producing actual samples for each variation. These Virtual Samples can be used to promote the product at the retail level, before production even begins, and is ideal for gauging demand beforehand. APEX3 also supports design and simulation in a variety of other industries such as circular knitting, weaving, pile weaving, and printing. (GK)

Fibre2Fashion News Desk – India