Toho Tenax, the core company of the Teijin Group’s carbon fibres and composites business, has made a lightweight multi-material roof cover for a fuel-cell bus made of carbon-fibre reinforced plastic (CFRP), aluminum and other lightweight engineering plastics. The roof cover can be manufactured in one large piece with complex shapes and can be mass produced.

The roof cover which boasts a visually appealing surface, is adopted for the world’s first mass-produced fuel-cell bus, which was developed by Toyota Motor Corporation.Toho Tenax, the core company of the Teijin Group's carbon fibres and composites business, has made a lightweight multi-material roof cover for a fuel-cell bus made of carbon-fibre reinforced plastic (CFRP), aluminum and other lightweight engineering plastics. The roof cover can be manufactured in one large piece with complex shapes and can be mass produced.#

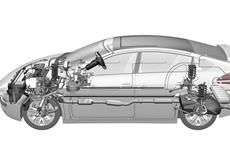

In the face of tightening environmental regulations worldwide, the automotive industry is developing lightweight vehicle bodies that achieve enhanced fuel efficiency while maintaining road stability. Since the bus carries high-pressure hydrogen gas tanks in its upper structure, lightweight body components in the top part of the vehicle are crucial.

Toho Tenax collaborated with GH Craft, the Teijin Group’s composite structure design, development and evaluation unit, to develop the multi-material roof by leveraging Toho Tenax’s high-performance carbon fibre and mass-production know-how and GH Craft’s molding technology.

Continental Structural Plastics Holdings Corporation (CSP), a global leader in automotive lightweight composite technologies, joined the Teijin Group in January 2017 to enhance global-development capabilities as a tier-1 supplier and solution provider of multi-material components and design. (SV)

Fibre2Fashion News Desk – India