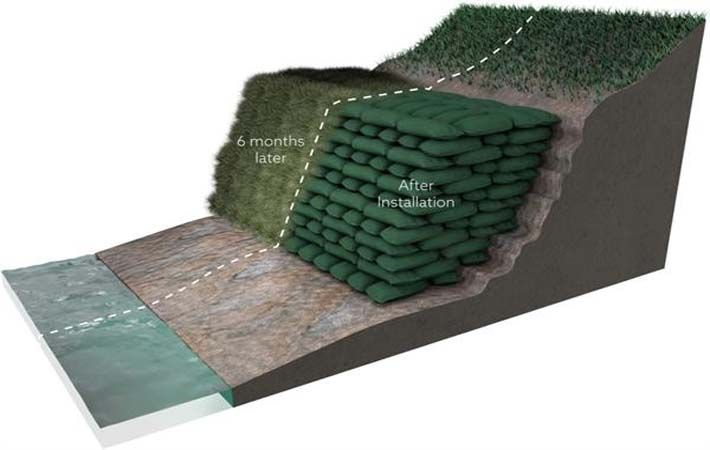

The supplies are delivered prefilled with Green-tree topsoil which negates the need to hand fill the bags and ensures a consistent and quality-controlled product. The geotextile bags, coupled with the Green-tree topsoil inside the bags allow for the establishment and promotion of vegetation growth, both on and inside the Bagwork. This greens up the Bagwork to improve its appearance, strengthens the structure and improves both riverbank habitat and biodiversity. Typically, vegetation is added by a technique called Hydroseeding. For Bagwork underwater, carbon-neutral concrete filled hand placed Bagwork is used to form a secure and sound foundation or base onto which the soil filled Bagwork can then be placed, the company said in a media statement.

“I am delighted to add SoluForm MSE Soil Filled Bagwork to our product offering. It is a cost effective, environmentally safe and ecologically beneficial form of riverbank, slope, or wall construction. It’s a simple yet clever idea and is ideal for landscape contractors and designers who have riverbanks or slopes in their schemes because you don’t need any specialist machinery or skilled labour. The bags are held together and prevented from moving by fixing spikes or plates between the rows of bags,” purchasing and product development manager, Chris Swan, said in a statement.

“We are proud to offer our new soil filled MSE Bagwork product and look forward to supplying Green-tech with a range of competitively priced products, which is backed up with our technical expertise and extensive bagging capabilities,” Andrew Mountain from SoluForm, said.

Fibre2Fashion News Desk (GK)