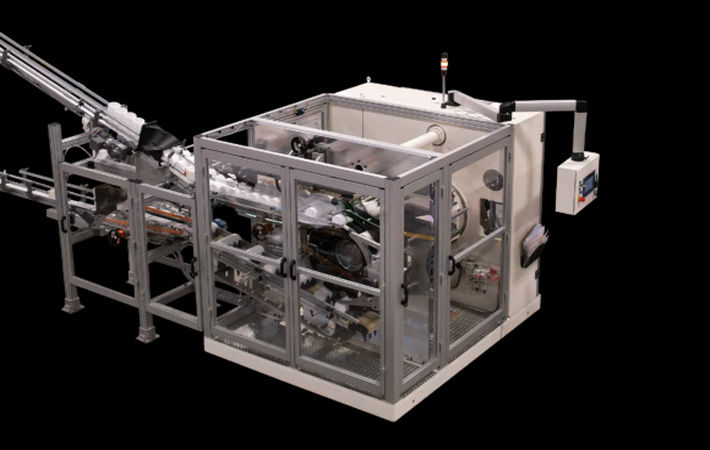

In reaction to COVID-19, Elsner has sold more ENR-Series machines than ever and have turned focus to providing solutions to keep the production not only moving but moving smoothly. The One-Eighty is built to typical Elsner standards with specifications that make production more efficient than ever. The name One-Eighty Canister Stuffer comes from the fact that the machine is built to reach 180 canisters per minute to match the output of the Elsner ENR-G3. The machine is also supported in the same ‘we’re always working for you’ Elsner way, the company said in a press release.

“When we are designing and building our equipment, we are always thinking ‘what is next? We try to think of what else we can automate and how we can deepen relationships with our customers. Stuffing has long been a pain point and we’ve worked to solve that challenge by designing a stuffer that’s fully integrated with our ENR-Series rewinder. We can now provide a full production line with a reduced number of suppliers from master roll to wipes in canisters,” said Jay Roth, Elsner’s director of sales.

“The challenge of linking the rewinder to the packaging equipment has been an issue for many of our customers. We took it upon ourselves as experts in the industry to master the transition and integration. The result is the ERS-180 that allows for the smoothest integration in the industry and a true turn-key solution,” Bert Elsner II, president/CEO of Elsner, said.

Fibre2Fashion News Desk (GK)