"MiniFIBERS has been a great partner as we begin our commercial journey. They've shown a great interest in finding ways to incorporate recycled content into their materials. In the past, fibre producers have experienced challenges when trying to use recycled polypropylene, because the varying level of contaminants cause the thread to break during the fibre manufacturing process. We remove those contaminants in our process at the molecular level, and in doing so, provide stronger product quality." PureCycle CEO Dustin Olson said.

"This trial is also a good example of PureCycle resin in a non-food grade application. Fibre represents approximately 15 per cent of the global demand for virgin polypropylene and to date, there hasn't been a scalable supply of recycled material to meet that demand. I believe this is one of the many areas where PureCycle resin can serve as a tangible replacement for fossil-based polypropylene,” explained Olson.

"These fabrics perform exactly the same as those manufactured with virgin polypropylene fibre, making them nearly plug and play for our customers. We see an endless number of applications where PureCycle's resin can be easily incorporated into the textile, transforming the fabric into a sustainable solution without any compromises. We are excited to work with current and future customers to integrate PureCycle's technology into cutting-edge fabrics, engineered for their specific needs,” Beverly Knits owner Ron Sytz said.

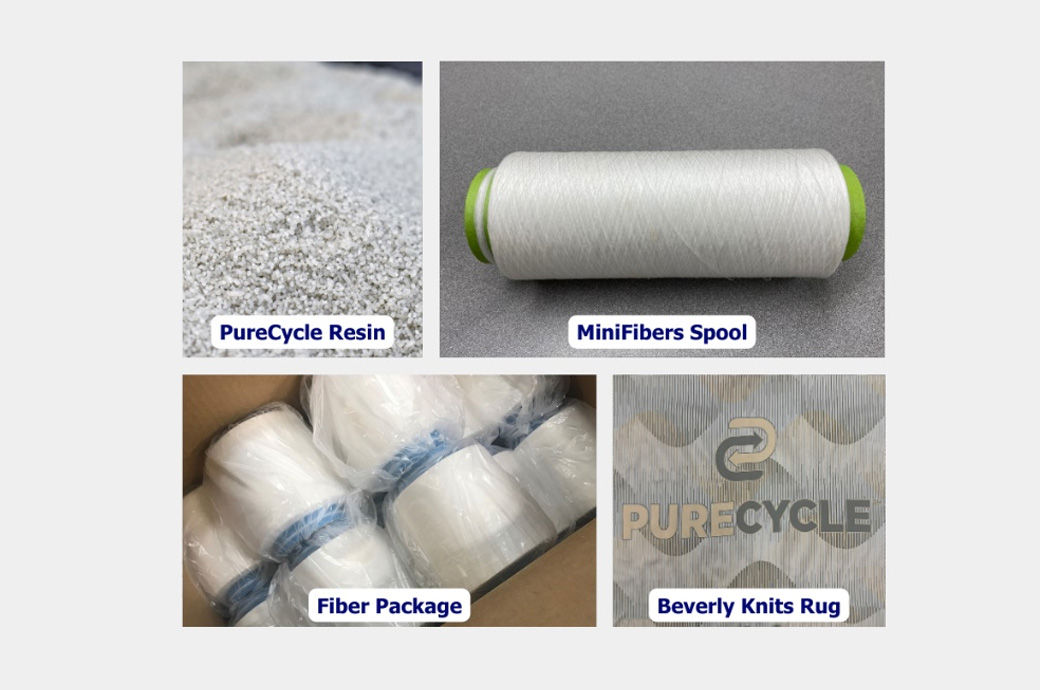

Polypropylene fibre is used in many industries, including apparel, textiles, and automotive. In early March, MiniFIBERS presented the PureCycle team with a rug made from 100 per cent PureCycle resin that was produced from post-industrial recycled (PIR) material, the company said in a press release.

"Brand owners everywhere are looking for a sustainable solution. These successful trials with PureCycle resin made from both PCR and PIR waste is a huge step forward for the industry and for sustainability. We look forward to continuing down this path with PureCycle and our partners at Beverly Knits to start producing sustainable commercial products that can soon be used by consumers,” MiniFIBERS sales director John Garner said.

PureCycle and MiniFIBERS plan to continue testing use cases for other nonwoven applications that could help improve the sustainability of products in the construction, automotive, and appliance industry.

Fibre2Fashion News Desk (RR)